TM-9-2320-272-24-2 - Page 812 of 991

TM 9-2320-272-24-2

4-16. FLYWHEEL HOUSING MAINTENANCE

THIS TASK COVERS:

a. Removal

c. Installation

b. Cleaning and Inspection

INlTlAL SETUP:

APPLICABLE MODELS

M939/A1

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Dial indicator (Appendix E, Item 36)

Soft-faced hammer

MATERIALS/PARTS

Nine lockwashers (Appendix D, Item 392)

Camshaft bore cork gasket (Appendix D, Item 32)

REFERENCES (TM)

TM 9-2320-272-24P

EQUIPMENT CONDITION

l

Flywheel ring gear removed (para. 4-15).

l

Engine oil pan removed (para. 4-22).

1.

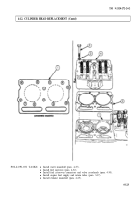

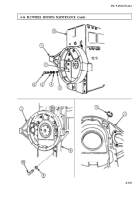

Remove nine screws (6), lockwashers (5), washers (4), and packing (3) from flywheel housing (1).

Discard lockwashers (5).

2.

Remove six screws (10) and lockwashers (9) from oil pan (8). Discard lockwashers (9).

3.

Tap around side of flywheel housing (1) with wood block and soft-faced hammer, and remove

flywheel housing (1) from dowel pins (7) in cylinder block (2).

4.

Remove camshaft bore cork gasket (11) from flywheel housing (1). Discard gasket (11) and clean

gasket remains from mating surfaces.

NOTE

Perform step 5 if installing new flywheel housing.

5.

Remove dowel pins (7) from cylinder block (2).

b. Cleaning and Inspection

1.

Clean flywheel housing (1) (para. 2-14). Ensure gasket mating surfaces are clean.

2.

Inspect flywheel housing (1) (para. 2-15). Discard flywheel housing (1) if defective.

3.

Inspect dowel pins (7) for damage and wear. Replace dowel pins (7) if damaged or outside diameter

is worn more than 0.5005 in. (12.71 mm).

4-130

Back to Top