TM-9-2320-272-24-2 - Page 826 of 991

TM 9-2320-272-24-2

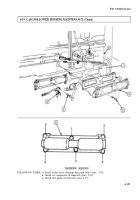

4-19. CAM FOLLOWER HOUSING MAINTENANCE

THIS TASK COVERS:

a. Removal

b. Disassembly

c. Cleaning and Inspection

d. Assembly

e. Installation

INITIAL SETUP:

APPLICABLE MODELS

M939/A1

TOOLS

General mechanic’s tool kit (Appendix E. Item 1)

Inside micrometer (Appendix E; Item 82)

Outside micrometer (Appendix E, Item 80)

Telescoping depth gauge (Appendix E, Item 136)

60-degree angle cutter (Appendix E, Item 6)

Feeler gauge, 0.006-in.

Soft-faced hammer

Arbor press

Mandrel

MATERIALS/PARTS

Two cup-plugs (Appendix D, Item 89)

Six screw-assembled lockwashers (Appendix D,

Item 586)

Cam follower housing gasket kit (Appendix D,

Item 534)

Lubricating oil (Appendix C, Item 50)

Prussian blue (Appendix C, Item 54)

Sealing compound (Appendix C, Item 68)

Drycleaning solvent (Appendix C, Item 71)

REFERENCES (TM)

TM 9-2320-272-24P

EQUIPMENT CONDITION

l

Fuel pump removed (cylinders 3 and 4)

(para. 4-35).

l

Air compressor removed (cylinders 1 and 2)

(para. 4-31).

l

Rocker lever housings and push tubes removed

(para. 4-20).

GENERAL SAFETY INSTRUCTIONS

l

Keep fire extinguisher nearby when using

drycleaning solvent.

l

Drycleaning solvent is flammable and toxic. Do

not use near an open flame.

NOTE

l

Maintenance procedure for all three cam follower housings are

the same.

l

Cam follower bushings are mounted with screw-assembled

lockwashers on late model engines.

NOTE

Removal of fuel line bracket is only required for number 2-3 cam

follower bushing.

1.

Remove six screw-assembled lockwashers (5) and fuel line bracket (6) from cam follower bushing (4).

Discard screw-assembled lockwashers (5).

4-144

Back to Top