TM-9-2320-272-24-2 - Page 832 of 991

TM 9-2320-272-24-2

4-19. CAM FOLLOWER HOUSING MAINTENANCE (Contd)

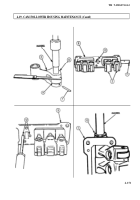

d. Assembly

1.

2.

3.

4.

5.

6.

7.

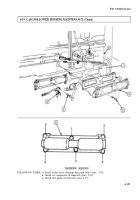

8.

9.

10.

11.

NOTE

l

Apply light coat of oil to all parts before assembly.

l

If new push tube insert is being installed, a new push tube

must also be used.

Install push tube insert (1) into cam follower lever (2). Ensure push tube insert (1) is securely

seated in cam follower lever (2).

Install cam follower lever bushing (3) into cam follower lever (2) with arbor press and mandrel.

Align oil hole (4) in cam follower lever bushing (3) with oil hole (5) in cam follower lever (2).

Chamfer each end of cam follower lever bushing (3) with 60-degree angle cutter. Clean all metal

chips from cam follower lever bushing (3) surfaces.

Place cam roller (8) into cam follower lever (2) with 0.006 in. (0.15 mm) feeler gauge between cam

follower lever (2) and cam roller (8).

Install roller pin (6) through cam roller (8) with arbor press and mandrel and align roller pin (6)

hole with hole in cam follower lever (2).

Install roller pin (6) on cam follower lever (2) with retainer pin (7).

Position six cam follower levers (2) into cam follower housing (9) in marked locations, and slide cam

follower shaft (11) through cam follower housing (9) and six cam follower levers (2).

Align screw hole in cam follower housing (9) with screw hole in cam follower shaft (11) with

temporary dummy screw (10) to prevent lockscrew (12) breakage when cup-plugs (13) are installed.

CAUTION

When pressing two cup-plugs into housing, press in only until

plugs are flush with cam follower housing to avoid lockscrew

breakage.

Coat two new cup-plugs (13) with sealing compound and press into cam follower housing (9) with

arbor press and mandrel. Press only until flush with cam follower housing (9).

Remove dummy screw (10) from cam follower housing (9).

Install two shaft lockscrews (12) through cam follower housing (9) into cam follower shaft (11).

4-150

Back to Top