TM-9-2320-273-34 - Page 561 of 801

TM9-2320-273-34

14-5. Cleaning.

Do not use a screwdriver to remove

carbon and scale as this may damage

the sealing surfaces.

a. Immerse parts in SD-2 drycleaning solvent (item 12, App B). Remove all carbon from valve

cavities as well as rust and scale from water cavities. Use compressed air to blow dirt from all cavities.

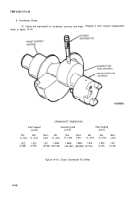

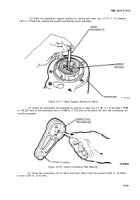

b. Clean oil passages in crankshaft and support with clean, dry compressed air. Using a stiff brush,

clean out the oil restrictive orifice (fig. 14-11).

TA 074367

Figure 14-11. Clean Out Oil Restrictive Orifice.

14-6. Inspection and Repair.

a. Cylinder Head Group.

(1) Check for visible cracks, breaks or mutilation in the compressor head (23, fig. 14-10).

14-14

CAUTIO N

Back to Top