TM-9-2320-273-34 - Page 569 of 801

TM9-2320-273-34

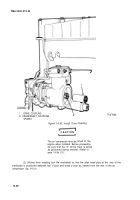

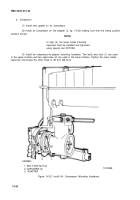

(11) Visually inspect the cylinder bore for scoring. Hone as needed.

(12) Check the crankcase cylinder bore for out-of-roundness and wear with a dial bore gage

(fig. 14-23). Bore and hone the cylinder bore to accommodate 0.010,0.020 or 0.030 in. (0.25, 0.50 or

0.76 mm) oversize pistons and rings with 150 grit stone if:

(a) Out-of-roundness exceeds 0.0015 in. (0.038 mm).

(b)

Bore is worn beyond 3.6285 in. (92.164 mm).

TA 074379

Figure 74-23. Check Cylinder Bore.

(13) A new crankcase cylinder bore is 3.625-3.626 in. (92.08-92.01 mm).

14-22

Back to Top