TM-9-2320-279-20-1 - Page 58 of 985

TM 9-2320-279-20-1

Table 2-1. Unit Level Preventive Maintenance Checks And Services

Item

Interval

Item To Be

No.

Inspected

Procedure

Not Mission

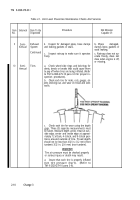

Capable If:

9

Semi-

Exhaust

b.

Annual

System

Inspect for damaged pipes, loose clamps

and leaking gaskets or seals.

b. Pipes

damaged,

clamps loose, gaskets or

Continued

seals leaking.

c.

Inspect raincap to make sure it operates

c. Raincap does not op-

freely.

erate freely, does not

close when engine is off,

or missing.

10

Semi-

Tires

a.

Annual

Check wheel side rings and lockrings for

dents, bends or breaks that could cause them

to pop off when tires are being inflated. (Refer

to TM 9-2320-279-10 para 3-9 for proper in-

spection procedures).

b

.

Check each tire for nicks, cuts, gouges, ob-

jects sticking out, and wear on tread and side-

walls.

c.

Check each tire for wear using tire depth

gage. Three (3) separate measurements must

be taken. Measure depth across tread at out.-

side edge, center and inside edge at approxi-

mately 12 o’clock, 4 o’clock, and 8 o’clock posi-

tions around outside of tire. Tread depth

should not be less than 4/32 in. (3.2 mm) (front

tandem) 3/32 in. (2.4 mm) (rear tandem).

WARNING

Tire air pressure must be checked properly

or serious injury or death may result.

d.

Insure that each tire is properly inflated

(see tire pressure chart).

(Refer to

TM 9-2320-279-10 para 3-9).

2-10

Change 3

Back to Top