TM-9-2320-280-20-2 - Page 216 of 951

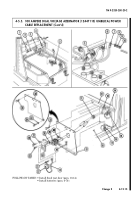

4-5.6. 100 AMPERE DUAL VOLTAGE ALTERNATOR REGULATOR (PART OF 12447110)

REPLACEMENT

This task covers:

a. Removal

b.

Installation

INITIAL SETUP:

Tools

General mechanic’s tool kit:

automotive (Appendix B, Item 1)

Maintenance and repair shop equipment:

automotive (Appendix B, Item 2)

Materials/Parts

Three lockwashers (Appendix G, Item 135)

Lockwasher (Appendix G, Item 138)

Sealant (Appendix C, Item 44)

Grease (Appendix C, Item 25)

Manual References

TM 9-2320-280-10

TM 9-2320-280-24P

Equipment Condition

• Battery ground cables disconnected (para. 4-73).

• Hood raised and secured (TM 9-2320-280-10).

NOTE

Prior to removal, tag leads for installation.

1.

Disconnect voltage regulator plug (21) from voltage regulator connector (19).

2.

Slide back rubber boot (13) and remove nut (14) and lead 568A (12) from IGN terminal (11).

3.

Slide back rubber boot (15) and remove nut (17) and lead 2A (16) from AC terminal (18).

4.

Remove nut (9) and ground wire (5) from 14-volt stud (10) on voltage regulator (23).

5.

Disconnect alternator connector (22) from voltage regulator connector (4).

6.

Remove screw (8), lockwasher (7), washer (6), and ground wire (5) from voltage regulator (23) and

alternator (20). Discard lockwasher (7).

7.

Remove three screws (3), lockwashers (2), washers (1), and voltage regulator (23) from

alternator (20). Discard lockwashers (2).

1.

Install voltage regulator (23) on alternator (20) with three washers (1), lockwashers (2), and screws (3).

Tighten screws (3) to 30-34 lb-in. (3-4 N

•

m).

2.

Install one end of ground wire (5) on voltage regulator (23) with washer (6), lockwasher (7), and

screw (8). Tighten screw (8) to 88-94 lb-in. (10-11 N

•

m).

3.

Install other end of ground wire (5) on 14-volt stud (10) with nut (9). Tighten nut (9) to 45-55 lb-in.

(5-6 N

•

m) and apply sealant to nut (9) and 14-volt stud (10).

4.

Connect alternator connector (22) to voltage regulator connector (4).

5.

Install lead 568A (12) on IGN terminal (11) with nut (14). Tighten nut (14) to 23-27 lb-in. (2.6-3.0 N

•

m).

6.

Apply grease to IGN terminal (11), lead 568A (12), and inside of boot (13), and slide rubber boot (13)

over terminal (11).

7.

Install lead 2A (16) on AC terminal (18) with nut (17). Tighten nut (17) to 18-22 lb-in. (2.0-2.5 N

•

m).

8.

Apply grease to AC terminal (18), lead 2A (16), and inside of boot (15), and slide rubber boot (15) over

terminal (18).

9.

Connect voltage regulator plug (21) to voltage regulator connector (19).

b. Installation

a. Removal

4-12.16

Change 3

TM 9-2320-280-20-2

Back to Top