TM-9-2320-280-34 - Page 338 of 1258

TM 9-2320-280-34

Change 1

6 - 1 8 . 3 3

6±-±3±

.±3±

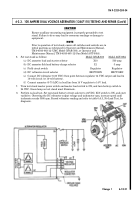

. 100 AMPERE DUAL VOLTAGE ALT±E±R±N±ATOR (12447110) TESTING AND REPAIR (Cont’d)

10.

Alternator speed and current output tracking values. Refer to table 6-A.5.

CONNECT

DISCONNECT

DIAGNOSIS

AMPS RISE

AMPS FALL

Alternator OK. See note. Replace regulator

only if low AMPS (40-59)/low VOLTS (21-25)

are indicated in table 6-A.3 and/or table 6-A.4.

NO CHANGE

NO CHANGE

Alternator must be repaired. Refer to static

testing, task c.

Table 6-A.6. Regulator Bypass Test.

11.

Perform regulator bypass test. Prepare alternator as in full-load test.

NOT E

• Perform this test only when instructed from tables 6-A.3 and 6-A.4.

• Use jumper wire rated for 15 amps.

12.

Disconnect alternator connector from regulator. With alternator spinning, use jumper wire and

short pin A to ground momentarily. Record results.

13.

Amperage should rise within ± 10 percent of rated value with jumper wire connected, and fall with

jumper disconnected. Refer to table 6-A.6, Regulator Bypass Test, for diagnosis.

14.

Turn test stand master power switch and load switch to OFF.

15.

Disconnect jumper wires from terminals on test stand and alternator.

16.

Remove belt from test stand pulley and alternator pulley. Remove alternator from test stand.

ALTERNATOR

28 VDC

14 VDC

SPEED

OUTPUT CURRENT

OUTPUT CURRENT

(RPM)

²5 AMP

MINIMUM AMP

25

36

2000

38

43

52

33

65

20

**85

0

*0

8

4000

25

32

to

48

52

8000

70

30

87

13

**100

0

Table 6-A.5. Alternator Speed and Current Tracking.

* Dependent on ammeter location in test circuit.

**Minimum acceptable current with no load on 28 VDC system.

ALTERNATOR

28 VDC

14 VDC

SPEED

OUTPUT CURRENT

OUTPUT CURRENT

(RPM)

²5 AMP

MINIMUM AMP

*0

26

10

31

1,200

25

23

35

13

48

0

*0

23

15

34

1,500

32

37

55

14

69

0

2,000

*0

20

Back to Top