TM-9-2320-280-34 - Page 339 of 1258

TM 9-2320-280-34

6 - 1 8 . 3 4

Change 1

6±-±3±

.±3±

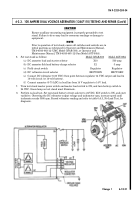

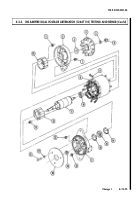

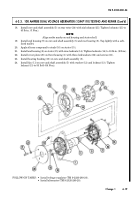

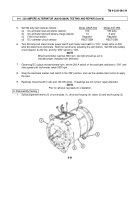

. 100 AMPERE DUAL VOLTAGE ALT±E±R±N±ATOR (12447110) TESTING AND REPAIR (Cont’d)

b. Disassembly

NOT E

Complete alternator disassembly is not required for static testing.

1.

Remove voltage regulator (TM 9-2320-280-20).

2.

Remove locknut (6), washer (5), fan (4), and bearing bushing (3) from core and shaft assembly (11).

Discard locknut (6).

3.

Remove three screws (21), lockwashers (22), and plate cover (20) from front housing (17). Discard

lockwashers (22).

4.

Scribe alignment marks on front housing (17), stator (9), and end housing (2).

5.

Remove nine locknuts (7) from end housing (2) and studs of stator (9). Discard locknuts (7).

6.

Using puller, remove end housing (2) from stator (9).

7.

Remove six locknuts (1) from rear rotor (24) and studs of core and shaft assembly (11). Discard

locknuts (1).

8.

Using three 10-32 x 2-in. long machine screws as jacks in threaded holes on end plate of rear

rotor (24), gradually tighten screws and remove rear rotor (24) from core and shaft assembly (11).

Remove machine screws.

NOT E

Prior to removal, tag leads for installation.

9.

Remove eight nuts (18) and disconnect two field and six phase leads (8) from diodes in front

housing (17).

10.

Remove nine locknuts (23) from front housing (17) and studs of stator (9). Discard locknuts (23).

11.

Remove shaft retaining ring (19) from core and shaft assembly (11).

12.

Remove front housing (17) from stator (9) by tapping lightly with a soft-faced mallet.

WARNING

Always support alternator core and shaft assembly during removal.

Failure to do so may cause injury to personnel or equipment damage.

13.

Using press, remove core and shaft assembly (11) from front bearing (15) and front housing (17).

14.

Remove front (16) and rear (14) retaining rings from front housing (17).

15.

Using press, remove front bearing (15) from front housing (17).

16.

Remove six locknuts (13) from front rotor (12) and studs of core and shaft assembly (11). Discard

locknuts (13).

17.

Using three 10-32 x 2-in. long machine screws as jacks in threaded holes on end plate of front

rotor (12), gradually tighten screws and remove front rotor (12) from core and shaft assembly (11).

Remove machine screws.

18.

Using press, remove rear bearing (10) from core and shaft assembly (11).

Back to Top