TM-9-2320-280-34 - Page 381 of 1258

This task covers:

a.

Alternator Output Testing

d.

Cleaning

b.

Disassembly

e.

Assembly

c.

Static Testing

a. Alternator Output Testing

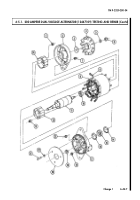

1.

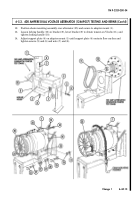

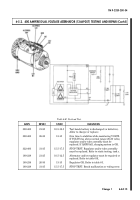

Mount 500-amp test stand pivot arm to high-speed side and install mounting flange adapter on pivot

arm. Connect pulley driveshaft to high-speed head. Install pulley driveshaft on mounting flange

adapter.

2.

Position adapter mount (1) to bracket (9) on test stand.

3.

Install adapter mount (1) on bracket (9) with washer (3), screw (2), washer (3), and nut (8).

Do not

tighten screw (2).

4.

Loosen locking handle (10) on bracket (9), raise bracket (9) to highest point, and tighten locking

handle (10).

5.

Install support plate (4) on adapter mount (1) with two washers (5), screws (6), washers (5), and

nuts (7). Do not tighten nuts (7).

6.

Install two V-belts (11) on driver pulley (12) on alternator/generator/starter test stand.

7.

Position alternator (25) on adapter mount (1) and install two V-belts (11) on pulley (15).

8.

Position two washers (22) between rear lower mount (24) on alternator (25) and adapter mount (1),

and install washer (21), screw (23), washer (21), and nut (20). Do not tighten nut (20).

9.

Align front lower mount holes (16) on alternator (25) and adapter mount (1) and install washer (18),

screw (19), washer (18), and nut (17). Do not tighten nut (17).

10.

Align top mount hole (26) on alternator (25) and adapter mount (1) and install two washers (13) and

screw (14).

11.

Tighten nuts (20) and (17) to 40 lb-ft (54 N

•

m).

INITIAL SETUP:

Applicable Models

M996, M996A1, M997, M997A1, M997A2

Tools

General mechanic’s tool kit:

automotive (Appendix G, Item 1)

Puller (Appendix G, Item 136)

Test Equipment

Multimeter (Appendix G, Item 120)

Test stand (Appendix G, Item 94)

Materials/Parts

RTV sealant (Appendix B, Item 43)

Silicone compound (Appendix B, Item 57)

Locknut (Appendix E, Item 65.2)

Locknut (Appendix E, Item 63)

Eighteen locknuts (Appendix E, Item 65.1)

Twelve locknuts (Appendix E, Item 65)

Twelve lockwashers (Appendix E, Item 92.1)

Two lockwashers (Appendix E, Item 88)

Two seals (Appendix E, Item 148.2)

Personnel Required

One mechanic

One assistant

Manual References

TM 9-2320-280-20

TM 9-2320-280-24P

TM 9-4910-663-12

TM 9-4910-485-12

Equipment Condition

Alternator removed (TM 9-2320-280-20).

General Safety Instructions

Always support alternator core and shaft assembly

during removal and installation.

Maintenance Level

Direct support

TM 9-2320-280-34

6 - 4 4 . 1 2

Change 1

6 - 5 . 2 . 400 AMPERE DUAL VOLTAGE ALT E R N ATOR (12469057) TESTING AND REPA

I R

Back to Top