TM-9-2320-361-20 - Page 219 of 1207

TM 9-2320-361-20

Table 2-4. Electrical Troubleshooting (Contd).

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

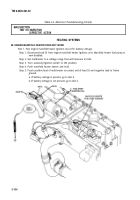

38. HORN DOES NOT OPERATE

NOTE

Electrical troubleshooting of the electric horn or air horn is the

same.

Test 1. Test input voltage to horn circuit breaker.

Step 1. Turn main light switch to SERVICE DRIVE position. If headlights light, there is voltage at

input of horn circuit breaker; turn headlights OFF.

Step 2. Remove lead 25 from horn circuit breaker.

Step 3. Set multimeter to a voltage range that will measure 24 Vdc.

Step 4. Connect negative lead to frame ground.

Step 5. Touch positive lead to horn circuit breaker contact.

a. If voltage is not present, replace horn circuit breaker (para. 4-33).

b. If voltage is present, go to test 2.

Test 2. Test air horn solenoid voltage.

Step 1. Remove lead 25 from pin B of air horn solenoid.

Step 2. Connect negative lead of multimeter to frame ground.

Step 3. Touch positive lead to pin B of solenoid.

a. If voltage is present, go to test 3.

b. If voltage is not present, go to step 6.

Step 4. Remove lead 25 connected to pin A of air horn solenoid. Connect negative lead to frame

ground. Touch positive lead to contact end of lead 25.

a. If voltage is present, replace air horn solenoid (para. 4-31).

b. If voltage is not present, replace or repair lead 25.

Test 3. Test horn switch input voltage.

Step 1. Remove horn button (para. 4-30) until lead 25 can be seen.

Step 2. Set multimeter to a voltage range that will measure 24 Vdc.

Step 3. Connect negative lead to frame ground.

Step 4. Touch positive lead to lead 25 contact end

a. If voltage is not present, replace or repair lead 25 (para. 4-51).

b. If voltage is present, go to test 4.

Test 4. Test horn switch continuity.

Step 1. Disconnect lead 25 from air horn solenoid to protect multimeter.

Step 2. Reinstall horn button cap, spring, and contact (para. 4-30).

Step 3. Set multimeter to RX1 scale.

Step 4. Connect negative lead to a good frame ground.

Step 5. Touch positive lead to lead 25 and press down until contact touches base plate.

a. If continuity is present, reconnect lead 25 and recheck horn operation.

b. If continuity is not present, remove horn button and clean or replace horn button

(para. 4-30).

2-134

Back to Top