TM-9-2320-361-20 - Page 459 of 1207

TM 9-2320-361-20

4-31. AIR HORN, SOLENOID, AND BRACKET REPLACEMENT

This task covers:

a.

Solenoid

Removal

c. Air Horn Installtion

b. Air Horn Removal

d. Solenoid Installation

INITIAL SETUP:

APPLICABLE MODELS

All

MATERIALS/PARTS

Four lockwashers

Antiseize tape (Appendix C, Item 27)

REFERENCES (TM)

TM 9-2320-361-10

TM 9-2320-361-20P

EQUIPMENT CONDITION

Parking brake set (TM 9-2320-361-10).

Hood raised and secured (TM 9-2320-361-10).

Battery ground cable disconnected (para. 4-48).

Air reservoirs drained (TM 9-2320-361-10).

GENERAL SAFETY INSTRUCTIONS

Do not disconnect air lines before draining air

reservoirs.

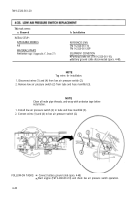

a. Solenoid Removal

WARNING

Do not disconnect air lines before draining air reservoirs. Small

parts under pressure may shoot out with high velocity, causing

injury to personnel.

1. Disconnect air line (2) from elbow (3).

2. Remove elbow (3) from air solenoid (4).

NOTE

Tag wires for installation.

3. Disconnect wire plugs (5) and (6) from air solenoid (4).

4. Remove air solenoid (4) and nipple (7) from air horn (1).

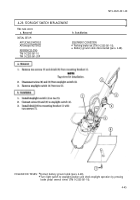

b. Air Horn Removal

1. Remove two nuts (10), lockwashers (11), screws (16), and air horn (1) from bracket (12). Discard

lockwashers(11).

2. Remove two nuts (14), lockwashers (13), screws (9), and bracket (12) from fender (15) and brace (8).

Discard lockwashers(13).

c. Air Horn Installation

1. Install bracket (12) on fender (15) with brace (8), two screws (9), new lockwashers (13), and

nuts (14).

2. Install air horn (1) on bracket (12) with two screws (16), new lockwashers (11), and nuts (10).

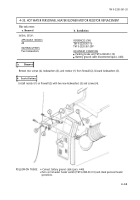

d. Solenoid Installation

NOTE

Clean all male pipe threads and wrap with antiseize tape before

installation.

1. Install nipple (7) and air solenoid (4) on air horn (1).

2. Install elbow (3) on air solenoid (4).

4-48

Back to Top