TM-9-2320-361-20 - Page 543 of 1207

TM 9-2320-361-20

7-10. FRONT AXLE SHAFT FLANGE MAINTENANCE

This task covers:

a. Removal

c. Installation

b. Cleaning and Inspection

INITIAL SETUP:

APPLICABLE MODELS

EQUIPMENT CONDITION

All

Parking brake

set (TM 9-2320-361-10).

MATERIALS/PARTS

GENERAL SAFETY INSTRUCTIONS

Gasket

Keep fire extinguisher nearby when

Eight lockwashers

drycleaning solvent.

GAA grease (Appendix C, Item 13)

Drycleaning solvent (Appendix C, Item 26)

Rags (Appendix C, Item 21)

REFERENCES (TM)

TM 9-2320-361-10

TM 9-2320-361-20P

using

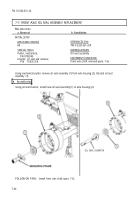

1. Remove eight screws (1) and lockwashers (2) from axle flange (3) and hub (5). Discard

lockwashers (2).

2. Loosen axle flange (3) from axle shaft (6).

3. Remove axle flange (3) and gasket (4). Discard gasket (4).

b. Cleaning and Inspection

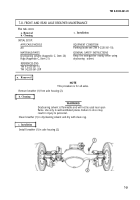

1. Clean gasket (4) remains from mating surfaces.

WARNING

Drycleaning solvent is flammable and will not be used near open

flame. Use only in well-ventilated places. Failure to do so may

result in injury to personnel.

2. Clean axle flange (3) in drycleaning solvent and dry with clean rag.

3. Clean gasket (4) surface on hub (5) with rag saturated with drycleaning solvent and dry with clean

rag.

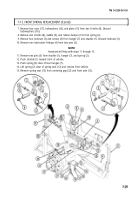

4. Inspect axle flange (3) for:

a.

Cracks and breaks. Replace if cracked or broken.

b.

Nicked, burred, or cracked female splines. Remove minor nicks or burrs with fine mill file or

emery cloth, Replace if splines are cracked.

c.

Inspect plug (7) for tightness. Replace if loose or leaking lubricant.

5. Inspect male splines on axle shaft (6) for nicks, burrs, or cracks. Remove minor nicks or burrs with

fine mill file or emery cloth. Replace axle shaft if splines are cracked (para. 7-6).

7-24

Back to Top