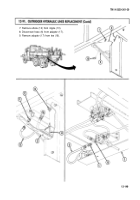

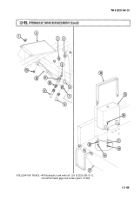

TM-9-2320-361-20 - Page 941 of 1207

12-95.

TM 9-2320-361-20

“

This task covers:

a. Removal

b. Installation

INITIAL SETUP:

APPLICABLE MODELS

REFERENCES (TM)

M764

LO 9-2320-209-12-1

MATERIALS/PARTS

TM 9-2320-361-10

TM 9-2320-361-20P

Six

locknuts

Sealing compound (Appendix C, Item 25)

EQUIPMENT CONDITION

Cap and plug set (Appendix

C, Item 8)

•Parking brake set (TM 9-2320-361-10).

PERSONNEL

REQUIRED

ŽHydraulic oil level gage and screen removed

(para. 12-88).

Two

CAUTION

When disconnecting hydraulic hoses, plug all openings to prevent

dirt from entering and causing internal parts damage. Remove

plugs prior to installation.

NOTE

ŽTag hoses for proper installation.

ŽHave

drainage

container

ready to catch oil.

1. Remove two locknuts (13), screws (1), and deflector (2) from crossmember (12). Discard locknuts (13).

2. Remove plug (5) and drain oil.

3. Remove hose (9), adapter (10), and tee (11) from nipple (3).

4. Remove hose (8), adapter (7), and elbow (6) from nipple (4).

5. Remove two locknuts (19), washers (20), and retainer (14) from body (21). Discard locknuts (19).

NOTE

Assistant will help with step 6.

6. Remove two locknuts (18), washers (17), screws (16), and hydraulic tank (15) from body (21).

Discard locknuts (18).

NOTE

ŽApply sealing compound to male pipe

•l Assistant will help with step 1.

threads before installation.

1. Install hydraulic tank (15) on body (21) with two screws (16), washers (17), and new locknuts (18).

2. Install retainer (14) on body(21) with two washers (20) and new locknuts (19).

3. Install elbow (6), adapter (7), and hose (8) on nipple (4).

4. Install tee (11), adapter (10), and hose (9) on nipple (3).

5. Install plug (5) on tee (11).

6. Install deflector (2) on crossmember (12) with two screws (1) and new locknuts (13).

12-158

Back to Top