TM-9-2320-361-20 - Page 945 of 1207

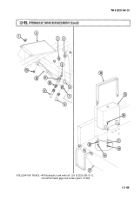

12-97.

TM 9-2320-361-20

This task covers:

a. Disassembly

c. Assembly

b. Inspection

INITIAL SETUP:

APPLICABLE MODELS

REFERENCES (TM)

MT64

TM 9-2320-361-20P

MATERIALS/PARTS

EQUIPMENT CONDITION

Safety wire (Appendix C, Item 22)

Snatch sheave removed (para. 12-98).

Graphite grease (Appendix C, Item 15)

1. Remove safety wire (4), screw (2), retaining pin (3), and pulley (7) from sheave housing (1). Discard

safety wire (4).

2. Remove bearing sleeve (5) from pulley (7).

1. Clean all parts (para. 2-10).

2. Check pulley (7) and sheave housing (1) for damage. Replace pulley (7) and sheave housing (1) if

damaged.

3. Check sleeve bearing (6) for nicks, cracks, burrs, or wear. Inside diameter should be no greater than

1.77 in. (45 mm). Raised metal can be removed with a fine mill file. Press sleeve bearing (6) out of

pulley (7) and replace sleeve bearing (6) if worn or damaged.

4. Check bearing sleeve (5) for nicks, burrs, cracks, or wear. Outside diameter should be no less than

1.735 in. (44.1 mm). Raised metal can be removed with a fine mill file. Replace bearing sleeve (5) if

worn or damaged.

1.

2.

3.

4.

5

Apply graphite grease inside sleeve bearing (6) and install bearing sleeve (5) in sleeve bearing (6).

Install pulley (7) in sheave housing (1).

Aline hole in bearing sleeve (5) with hole in sheave housing (1) and install retaining pin (3) in

sheave housing (1).

Install screw (2) in sheave housing (1).

Aline hole in screw (2) with hole in sheave housing (1), and install new safety wire (4) in screw (2)

and sheave housing (1).

12-162

Back to Top