TM-9-2320-361-24-1 - Page 216 of 1176

TM 9-2320-361-24-1

0013 00

0013 00-4

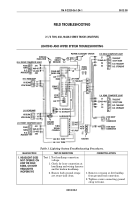

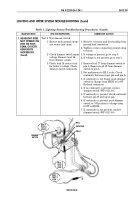

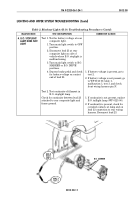

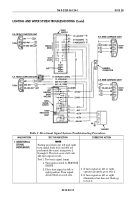

LIGHTING AND WIPER SYSTEM TROUBLESHOOTING (Contd)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. HEADLIGHT DOES

NOT OPERATE ON

LOW OR HIGH

BEAM, OR BOTH

HEADLIGHTS

INOPERATIVE

(Contd)

Test 3. Test lighting system harness

connector to voltage.

1. Turn main light switch lever to

OFF position.

2. Remove light switch assembly

from instrument panel

(WP 0101 00).

3. Disconnect harness connector

from light assembly

(WP 0101 00).

CAUTION

Voltage at pin F is tied directly to

battery without fuse protection. Insert

jumper wire in pin of faulty circuit

being tested first to prevent energized

jumper wire from touching ground and

damaging wire harness.

4. Check for battery voltage at

harness connector at pin F.

5. Check circuit 15 for loose

connections or broken wire.

6. Reconnect front wiring harness

connector to light switch and

reinstall light switch

(WP 0101 00).

1. If battery voltage is indicated at pin

F, connect a jumper wire from pin F

to socket pin of faulty circuit.

2. If lamps light with jumper wire

connected, replace main light switch

(WP 0101 00).

3. If battery voltage is not indicated,

go to step 5.

Repair broken wire.

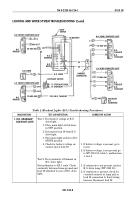

MAL 1

TEST 3

STEP 4

MAIN LIGHT SWITCH

HARNESS CONNECTOR

SOCKET WIRE NO.

CIRCUIT

A

B

C

D

E

F

H

J

K

L

M

N

75

40

22

19

20–24

15

21

460–461

75

491

16

23

STOPLIGHT SWITCH

PANEL LIGHTS

DIRECTIONAL CONTROL

BLACKOUT (B.O.) DRIVING LIGHT

B.O. MARKER LIGHTS

BATTERY POSITIVE CABLE 24 VOLTS

SERVICE REAR LIGHTS

DIRECTIONAL INDICATOR

STOPLIGHT SWITCH

SERVICE PARKING LIGHTS

SERVICE HEADLIGHTS

B.O. STOPLIGHT

Table 1. Lighting System Troubleshooting Procedures (Contd).

N

H

J

F

E

M

D

C

L

B

A

K

Legend

Back to Top