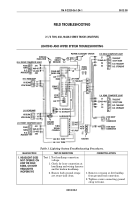

TM-9-2320-361-24-1 - Page 206 of 1176

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. NO ALTERNATOR

OUTPUT

5. Measure voltage at terminal

end of lead 568.

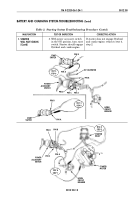

Test 4. Test positive output of

alternator.

NOTE

• Access cover was removed in test 3.

• Input amps decrease in input

voltage normally causes an increase

in alternator output voltage.

1. Start engine

(TM 9-2320-361-10).

2. Set engine speed at 1200 RPM.

3. Turn headlights and

accessories to ON position.

4. Use multimeter to measure

alternator output voltage at

positive terminal (lead 2).

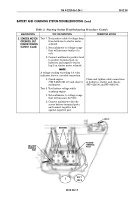

Test 5. Test voltage drop on lead 2.

Place multimeter positive lead

on alternator positive output.

Place multimeter negative

lead on starter solenoid lug 2.

Test 6. Test battery voltage into

power accessory switch

(WP 0012 00, table 3,

malfunction 1, test 4).

1. Disconnect lead 1 from pin D

of power accessory switch.

2. Turn power accessory switch

to ON position.

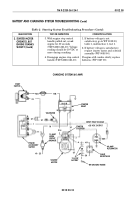

1. If battery voltage is present

(normal), the alternator is

defective. Go to test 4 and check

positive output of alternator.

2. If voltage is not present, an open

lead or bad connection exists in

lead 568. Repair or replace lead

(WP 0090 00). Return to test 2.

1. If output voltage is between 24.0

and 26.0 VDC, replace alternator

(WP 0085 00).

2. If output voltage is more than

28.5 VDC, go to test 5 and check

voltage drop on lead 2.

1. If voltage drop on lead 2 is greater

than 0.4 volts, repair or replace

lead (WP 0090 00). Go to test 2.

2. If voltage drop on lead 2 is less

than 0.4 volts (normal), voltage

regulator output is too high.

Replace alternator (WP 0085 00).

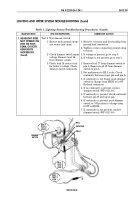

TM 9-2320-361-24-1

0012 00

0012 00-22

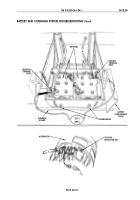

BATTERY AND CHARGING SYSTEM TROUBLESHOOTING (Contd)

Table 3. Charging System (60 Amp) Troubleshooting Procedure (Contd).

Back to Top