TM-9-2320-361-24-1 - Page 200 of 1176

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. STARTER MOTOR

OPERATES, BUT

ENGINE CRANKS

SLOWLY (Contd)

NOTE

A voltage reading exceeding 0.2 volts

indicates bad connection at starter

motor terminal lug 3 and terminal 6

of solenoid lug.

3. Crank engine

(TM 9-2320-361-10) and

observe multimeter.

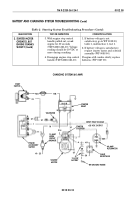

Test 5. Test starter motor solenoid

contact voltage drop.

1. Set multimeter to voltage

range that will measure

tenths of a volt.

2. Connect multimeter between

starter motor solenoid

terminal lugs 2 and 3.

NOTE

A voltage reading exceeding 0.4 volts

indicates defective starter motor

solenoid.

3. Crank engine

(TM 9-2320-361-10) and

observe multimeter.

Test 6. Test negative cable 7 voltage

drop from batteries to starter

motor.

1. Set multimeter to voltage

range that will measure

tenths of a volt.

2. Connect multimeter positive

lead to terminal stud on end

plate of starter motor and

negative lead to frame

ground.

NOTE

A voltage reading exceeding 0.4 volts

indicates defective starter motor

solenoid.

3. Crank engine

(TM 9-2320-361-10) and

observe multimeter.

Clean and tighten connections

WP 0088 00).

1. Replace starter motor and solenoid

assembly (WP 0088 00).

2. If malfunction still exists, go to

tests 6, 7, and 8.

1. Replace starter motor and solenoid

assembly (WP 0088 00).

2. If malfunction still exists, go to

tests 7 and 8.

TM 9-2320-361-24-1

0012 00

0012 00-16

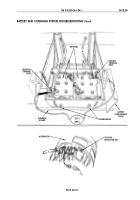

BATTERY AND CHARGING SYSTEM TROUBLESHOOTING (Contd)

Table 2. Starting System Troubleshooting Procedure (Contd).

Back to Top