TM-9-2320-361-24-1 - Page 192 of 1176

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. STARTER WILL NOT

CRANK (Contd)

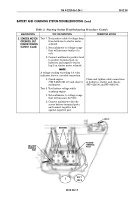

Test 2. Test for battery voltage at lug

D of magnetic starter relay.

1. With power accessory switch

ON, turn start switch and at

same time, check for battery

voltage at lug D on starter

relay.

2. Set multimeter to RX 1 scale.

Check for continuity between

lug C on starter relay and

ground.

3. Check for battery voltage at

lug B of starter relay with

start switch turned.

4. Check for battery voltage at

lug A on starter relay. Voltage

should always be present.

5. Check continuity of lead 214

between lug B on starter relay

and pin 1 on starter solenoid.

1. If 19 VDC are not present, go to

test 4.

2. If voltage is present, go to test

step 2.

1. If continuity is 1 ohm or less, go to

test step 3.

2. If continuity is greater than 1 ohm,

disconnect ground lead at lug C.

Repair or replace ground lead

(WP 0090 00). Go to WP 0012 00,

table 1, malfunction 1, test 1, step

1 and retest.

1. If voltage is present, go to test

step 5.

2. If voltage is not present, go to test

step 4.

If voltage is not present, repair or

replace lead 14 (WP 0090 00). Go to

WP 0012 00, table 1, malfunction 1,

test 1, step 1 and retest.

If continuity is not present, repair or

replace lead 214 (WP 0090 00). Clean

connections before reinstalling lead.

Ensure all connections are tight. Go

to WP 0012 00, table 1, malfunction 1,

test 1, step 1 and retest.

TM 9-2320-361-24-1

0012 00

0012 00-8

BATTERY AND CHARGING SYSTEM TROUBLESHOOTING (Contd)

Table 2. Starting System Troubleshooting Procedure (Contd).

Back to Top