TM-9-2320-361-24-1 - Page 185 of 1176

TM 9-2320-361-24-1

0012 00

0012 00-1

FIELD TROUBLESHOOTING

2-1/2 TON, 6X6, M44A2 SERIES TRUCKS (MULTIFUEL)

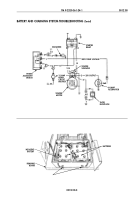

BATTERY AND CHARGING SYSTEM TROUBLESHOOTING

WARNING

• Battery acid (electrolyte) is extremely harmful. Always wear

safety goggles and rubber gloves when performing battery

maintenance. Severe injury will result if acid contacts eyes or

skin.

• Do not smoke, use open flame, or make sparks when

performing battery maintenance. Batteries may explode,

causing severe injury to personnel.

• Remove all jewelry, such as rings, identification tags,

bracelets, etc. If jewelry or disconnected battery ground cable

contacts battery positive post, a direct short can result,

causing damage to equipment or severe injury to personnel.

• When removing cables, disconnect the ground cable first. Do

not allow tools to come into contact with vehicle when

disconnecting cable clamps. A direct short can result, causing

instant heating of tools, tool damage, battery damage or

battery explosion, and severe injury to personnel.

CAUTION

• During installation of battery terminals, ensure positive

clamps are installed on positive (+) posts and negative clamps

are installed on negative (-) posts. Failure to connect clamps

to correct posts will reverse polarity of circuitry and may

cause damage to rectifier diodes in alternator, vehicle wiring,

and radios (if equipped).

• Do not use a hammer during installation of battery terminal.

Doing so may cause damage to equipment.

NOTE

• Refer to general troubleshooting instructions in the

Introduction to Troubleshooting Work Package (WP 0004 00)

prior to performing any battery and charging system

troubleshooting.

• The electrical systems troubleshooting procedures use

multimeters in resistance or continuity tests and voltage or

low ampere current tests. Multimeters may be found in the

Common no. 1 and no. 2 Unit Maintenance Automotive Shop

Sets.

• The electrical wiring schematic for the M44A2 series truck

can be found in WP 0473 00.

Back to Top