TM-9-2320-361-24-1 - Page 186 of 1176

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ALL VEHICLE

ELECTRICAL SYSTEMS

INOPERATIVE

1. Open door of battery compartment.

Loosen two thumbscrews and slide

batteries onto running board.

Visually check connections of

battery cables (WP 0127 00).

2. Visually check batteries for cracks

and leaks. Check terminal posts for

corrosion and breaks

(TM 9-6140-200-14).

Test 1. Check specific gravity of each

cell before adding distilled

water.

1. Using optical battery tester,

which requires no

temperature compensation,

check specific gravity of

electrolyte in each cell.

2. Check specific gravity of cells

after battery has been

charged (TM 9-6140-200-14).

Ensure battery cables are correctly

connected to battery (WP 0126 00).

1. If any battery is cracked, leaking,

or has broken terminal posts,

replace battery (WP 0127 00).

2. If terminal posts or cables are

corroded, use soda-and-water

solution to neutralize battery acid.

3. Remove battery ground cable no. 7

from negative post first. Remove

cable clamps from battery posts.

Clean posts and mating surfaces to

bright metal (WP 0126 00).

4. If battery terminals are clean and

malfunction still exists, go to

test 1.

If specific gravity of any cell is below

1.225, battery must be replaced or

recharged. Add distilled water as

necessary after checking battery.

Charge battery as necessary.

(TM 9-6140-200-14).

1. If specific gravity of any cell does

not increase to 1.280 (full charge)

in 8 hours of charging, replace

battery (WP 0127 00).

2. All cells in a battery must test

within 0.025 point of one another.

If specific gravity of any cell is

lower than 1.225 (corrected to

80 °F [27 °C] if necessary) after 8

hours of charging, replace battery

(WP 0127 00).

TM 9-2320-361-24-1

0012 00

0012 00-2

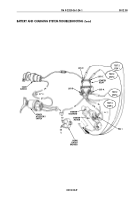

BATTERY AND CHARGING SYSTEM TROUBLESHOOTING (Contd)

Table 1. Battery System Troubleshooting Procedure.

Back to Top