TM-9-2320-361-24-1 - Page 190 of 1176

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. STARTER WILL NOT

CRANK

NOTE

• Ensure transmission is in neutral.

• Check batteries and cables. (See

WP 0012 00, table 1, malfunction 1,

step 1.)

Test 1. Test for battery voltage at pin

1 of starter solenoid with

power accessory switch turned

to ON position.

1. Turn start switch and listen

for starter solenoid with

power accessory switch turned

to ON position.

2. Check lead 6 at starter

solenoid for battery voltage.

3. Check lead 214 for battery

voltage at pin 1 of starter

solenoid.

4. Set multimeter to RX 1 scale.

Check continuity between pin

4 of starter solenoid and

frame ground.

5. Check battery cables for

voltage drop (WP 0012 00,

table 2, malfunction 2, tests 4

through 7).

1. If a thump sound is heard, go to

step 2.

2. If thump sound is not heard, go to

step 3.

3. Check for seized engine. Refer to

WP 0006 00, table 1, malfunction 1,

step 3.

1. If voltage is present but less than

19 VDC, check for corrosion and/or

loose connections.

2. If no voltage is present and engine

still fails to start, go to step 3.

1. If voltage is not present, go to

test 2.

2. If voltage is present and solenoid

does not engage starter motor,

proceed to step 4.

1. If continuity is greater than 1 ohm,

remove starter solenoid and starter

motor ground cables (WP 0088 00).

Repair or replace cables

(WP 0126 00 and WP 0090 00) that

have resistance greater than

1 ohm. Clean cable ends. Clean

connections on starter motor and

frame ground. Reconnect ground

cables and ensure all connections

are tight. Repeat test 1, step 1.

2. If continuity is greater than 1 ohm,

starter solenoid is defective.

Replace starter motor

(WP 0088 00).

If voltage is not present, clean and

tighten cable connections

(WP 0126 00).

TM 9-2320-361-24-1

0012 00

0012 00-6

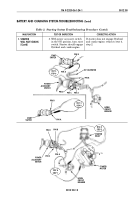

BATTERY AND CHARGING SYSTEM TROUBLESHOOTING (Contd)

Table 2. Starting System Troubleshooting Procedure.

Back to Top