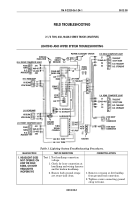

TM-9-2320-361-24-1 - Page 204 of 1176

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. NO ALTERNATOR

OUTPUT

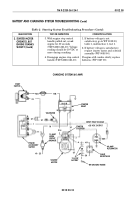

6. Check voltage regulator

stability.

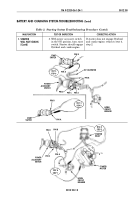

Test 3. Test input voltage to alternator.

1. Turn headlights to OFF

position. Stop engine.

2. Disconnect lead 1 from lead 568

at alternator.

3. Turn power accessory switch to

ON position.

4. Check for battery voltage at

contact end of lead 1. Voltage

should be 24.0 VDC.

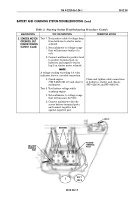

5. If alternator voltage across

batteries cannot be adjusted to

28.0 ± 0.2 VDC, replace alternator

(WP 0085 00).

6. If battery voltage is greater than

30.0 VDC, first try to adjust voltage

regulator in alternator down to

28.0 VDC. If voltage regulator

voltage cannot be adjusted to 28.0

VDC, replace alternator (WP 0085

00).

1. Decrease engine speed to 1000

RPM with headlights in ON

position. Regulated battery voltage

should remain at 28.0 ± 0.2 VDC.

2. If battery voltage drops below

27.5 VDC, replace alternator

(WP 0085 00).

3. Increase engine speed to 2000

RPM. Regulated battery voltage

should remain at 28.0 ± 0.2 VDC.

4. If battery voltage increases above

28.5 VDC, replace alternator

(WP 0085 00).

5. Return engine speed to 1200 RPM.

6. Turn headlights on and off and

observe change in battery voltage.

7. If battery voltage changes more

than ± 0.5 VDC and does not

return quickly to 28.0 ± 0.2 VDC,

replace alternator (WP 0085 00).

1. If voltage is not present, open lead

or bad connection exists in input

circuit. Go to test 6.

2. If voltage is 24.0 VDC (normal),

remove access cover on top of

alternator to expose output terminal.

3. Reconnect lead 1 to lead 568. Go to

test step 5.

TM 9-2320-361-24-1

0012 00

0012 00-20

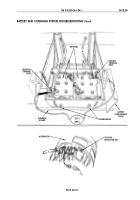

BATTERY AND CHARGING SYSTEM TROUBLESHOOTING (Contd)

Table 3. Charging System (60 Amp) Troubleshooting Procedure (Contd).

Back to Top