TM-9-2320-361-24-1 - Page 230 of 1176

TM 9-2320-361-24-1

0013 00

0013 00-18

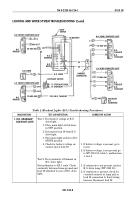

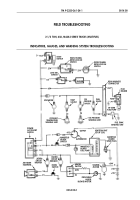

LIGHTING AND WIPER SYSTEM TROUBLESHOOTING (Contd)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. ALL STOPLIGHTS

ARE INOPERATIVE

Test 1. Check stoplight switch for

input voltage.

1. Turn main light switch to

SERVICE DRIVE position.

2. Set multimeter to voltage

range that will measure

24 VDC.

3. Disconnect lead 75 input

voltage from stoplight switch.

4. Touch positive lead of

multimeter to contact end of

lead 75.

5. Touch negative lead of

multimeter to frame ground.

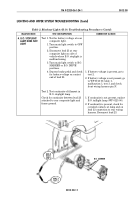

Test 2. Check stoplight switch for

output voltage.

1. Set multimeter to voltage

range that will measure

24 VDC.

2. Disconnect output lead 75 from

stoplight switch.

3. Touch positive lead of

multimeter to contact end of

stoplight switch.

4. Touch negative lead of

multimeter to frame ground.

5. Depress brake pedal.

6. Place main light switch in OFF

position.

7. Set multimeter to RX 1 scale.

8. Place positive lead of

multimeter in pin A of wiring

harness.

9. Place negative lead on input

lead 75 at stoplight switch.

NOTE

If vehicle is equipped with hydraulic

stoplight switch and switch is

defective, replace air-activated

stoplight switch conversion kit, part

number 12255668.

1. If voltage is present, go to test 2.

2. If voltage is not present, go to

WP 0013 00, table 1, malfunction 1,

test 3. Depress brake pedal and

check lead 75.

If voltage is not present, and

stoplights are still inoperative, go to

step 6.

1. If continuity is present, replace

stoplight switch (WP 0112 00).

2. If continuity is not present, repair or

replace wire or wiring harness.

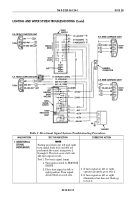

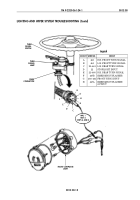

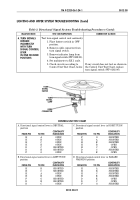

Table 3. Directional Signal Systems Troubleshooting Procedures (Contd).

Back to Top