TM-9-2320-361-34 - Page 447 of 764

TM 9-2320-361-34

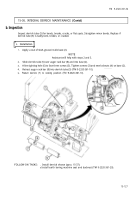

15-38. BORING

CASE MAINTENANCE (Contd)

d. Cleaning, Inspection, and Repair

1.

2.

3.

4.

For general cleaning instructions, refer to para. 2-8.

Inspect rack feed gear (34), spur pinion (12), rack drive gear (24), rack feed idler gear (23), spur pinion

shaft (19), rack feed gearshaft (20), thrust roller shaft, (11), and carrier (8) for burrs, chips, cracks,

damaged teeth, or splines. Burrs maybe removed with a fine mill file. Replace component if damaged.

NOTE

Rack drive gear, rack feed idler gear, and rack feed spur pinion

must each be replaced with associated pinion as a matched set.

Inspect thrust plates (9) and (10), rack thrust roller (5), thrust bearings (29) and (3), and thrust

washer (15) for wear or other damage. Refer to table 15-4, Boring Case Wear Limits, for

measurements. Replace if worn or otherwise damaged.

Inspect all bearings for wear or other damage (TM 9-214). Replace bearings if worn or damaged.

Table 15-4. Boring Case Wear Limits.

ITEM

WEAR LIMITS/TOLERANCES

NO.

lTEM/POINT OF MEASUREMENT

INCHES

MII.I.IMETERS

5

Rack thrust roller:

Inside diameter

1.750-1.753

44.45-44.53

Outside diameter

3.328-3.330

84.53-84.58

9

Thrust plate (thickness)

0.370-0.376

9.40-9.55

10

Thrust plate (thickness)

0.307-0.313

7.80-7.95

15

Thrust washer (thickness)

0.140-0.145

3.56-3.68

29&3

Thrust bearing (thickness)

0.734-0.765

18.64-19.43

I

e. Boring Gear Assembly

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Pack inner bearing (13) and outer bearing (14) with GAA grease and install in spur pinion

(12).

Install thrust washer (15), retaining pin (16), and spur pinion (12) in rack carrier (8) with spur

pinion shaft (19) and setscrew (18).

Pack two bearings (36) with GAA grease and install on rack feed gear (34).

Install new seal (33) and new seal retainer (32) on rack feed gear (34).

Install rack feed gear (34) in rack

carrier

(8)

with rack feed gearshaft (20), thrust bearing (29), nut (31),

and new cotter pin (30). Tighten setscrew (35).

Pack bearing (4) with GAA grease and install in rack thrust roller (5).

Install rack thrust roller (5) in rack carrier (8) with thrust roller shaft

(11),

thrust bearing (3), nut (2),

and new cotter pin (1).

NOTE

For steps 8 through 11, new shims must be the same thickness as

recorded in removal.

Pack roller bearing (6) with GAA grease and install new shims (7) and roller bearing (6) on rack

carrier (8).

Install new shims (25) and rack drive gear (24) on rack carrier (8) with three screws (17) and nine

screws

(28).

Pack roller bearings (22) and (27) with GAA grease.

Install new shims (21), roller bearing (22), rack feed idler gear (23), and roller bearing (27) on rack

carrier

(8)

with adjusting nut (26).

Tighten adiusting nut (26) until rack feed idler gear (23) has no in and out play then back off

adjusting nut (26) 1/8 turn.

.

15-136

Back to Top