TM-9-2320-361-34 - Page 437 of 764

TM 9-2320-361-34

15-36.

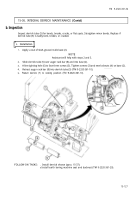

INTEGRAL DERRICK MAINTENANCE

THIS TASK COVERS:

a.

Removal

c. Installation

b. Inspection

INITIAL

SETUP

APPLICABLE MODELS

REFERENCES (TM)

M764

TM 9-2320-361-10

TOOLS

TM 9-2320-361-34P

General mechanic’s tool kit

EQUIPMENT CONDITION

(Appendix B, Item 1)

●

Parking brake set (TM 9-2320-361-10).

MATERIALS/PARTS

●

Outrigger arms lowered (TM 9-2320-361-10).

. Derrick sheave removed (para. 15-37).

GAA grease (Appendix C, Item 8)

Three locknuts (Appendix F, Item 105)

GENERAL SAFETY INSTRUCTIONS

PERSONNEL REQUIRED

●

Do

not

lower

derrick below horizontal position.

. Derrick tube is heavy. Provide adequate support

Two

when removing or installing derrick tube.

WARNING

.

During removal and installation, only two teeth of worm leveling

gear support derrick in horizontal position. Do not lower derrick

below horizontal or derrick may fall and cause injury or death to

personnel.

●

Derrick

tube is heavy. Provide adequate support for derrick tube

during removal and installation over rack bar. Failure to do so

may result in injury or death to personnel.

NOTE

Before removal of derrick, ensure there is 20 ft (6 m) clearance to

the right of vehicle and 6 ft (2 m) clearance to the left of the vehicle.

a. Removal

1. Lower derrick (7) to near horizontal and manually turn horizontal leveling worm gearshift (1) until

derrick (7) is horizontal (TM 9-2320-361-10). Worm gear (10) will hold two teeth of worm wheel (9).

CAUTION

Do not feed rack bar more than 6 ft (2 m) from bottom of boring case

while in horizontal position. Weight of rack bar may cause damage

to pinions in boring gearcase.

2. Feed

auger rack bar (8) 5 ft (1.5 m) out of derrick (7) (TM 9-2320-361-10).

NOTE

Assistant will help with step 3.

3. Loosen three locknuts (4) and screws (3) and remove derrick tube bar (5) from base (2) and auger

rack bar (8). Discard locknuts (4).

15-126

Back to Top