TM-9-2320-361-34 - Page 439 of 764

TM 9-2320-361-34

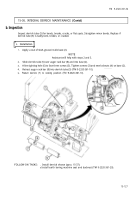

15-37. DERRICK SHEAVE MAINTENANCE

THIS TASK COVERS:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Cleaning and Inspection

INITIAL SETUP

APPLICABLE MODELS

REFERENCES (TM)

M764

TM

9-237

TM 9-2320-361-10

TOOLS

TM 9-2320-361-34P

General mechanic’s tool kit

(Appendix B, Item 1)

EQUIPMENT CONDITION

Outside micrometer (Appendix B, Item 17)

Parking brake set (TM 9-2320-361-10).

MATERIALS/PARTS

Lockwasher (Appendix F, Item 141)

Two locknuts (Appendix F, Item 108)

Graphite grease (Appendix C, Item

9)

a. Removal

Loosen two screws (11) and remove support block (4) from derrick tube (10).

b. Disassembly

1. Remove nut (6), lockwasher (5), screw (12), and pulley (1) from support block

(4).

Discard

lockwasher (5).

2.

Remove bearing sleeve (3) from pulley (1).

3. Remove two locknuts (7), screws (9), and sheave cover (8) from support block (4). Discard

locknuts (7).

I

c. Cleaning and Inspection

1. Clean all parts (para. 2-8).

2. Check support block (4) for cracks and other damage. If cracked, repair support block (4) by

welding (TM 9-237). Replace if otherwise damaged.

3. Check pulley (1) for cracks and other damage. Replace pulley (1) if worn or damaged.

4. Check bearing sleeve (3) for nicks, burrs, cracks, and wear. Outside diameter should be no less than

1.475 in. (37.5 mm). Raised metal can be removed with a fine mill file. Replace bearing sleeve (3) if

worn or damaged.

5. Check sheave cover (8) for bends and other damage. Straighten if bent. Replace sheave cover (8) if

damaged.

1. Install sheave cover (8) on support block (4) with two screws (9) and new locknuts (7).

2. Apply

graphite grease in bearing (2) and install bearing sleeve (3) in pulley (1).

3. Install

pulley (1), screw (12), new lockwasher (5), and nut (6) in support block (4).

d. Assembly

e. Installation

Install support block (4) in derrick tube (10) and tighten two screws (11).

15-128

Back to Top