TM-9-2320-366-20-5 - Page 378 of 1158

TM 9-2320-366-20-5

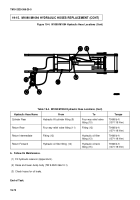

19-13. HYDRAULIC OIL FILTER ASSEMBLY SERVICE/REPLACEMENT

This task covers:

a. Service

b. Removal

c. Installation

d. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Engine shut down (TM 9-2320-366-10-1).

Tools and Special Tools

Tool Kit, Genl Mech (Item 46, Appendix C)

Wrench, Torque, 0-175 lb-ft (Item 58, Appendix C)

Pan, Drain (Item 24, Appendix C)

Materials/Parts

Filter Element, Fluid (Item 20, Appendix G)

(Service)

Seal, Plain (Item 271.1, Appendix G) (Service)

Dispenser, Pressure Sensitive Adhesive Tape

(Item 20, Appendix D)

Tape, Antiseizing (Item 66, Appendix D)

Oil, Lubricating, OE/HDO 10W (Item 43,

Appendix D)

Filter Element, Fluid (Item 20, Appendix G)

Packing, Preformed (2) (Item 180, Appendix G)

a. Service.

(1) Remove hydraulic oil filter assembly bowl (1) from filter

assembly base (2).

(2) Remove fluid filter element (3) from oil filter assembly

base (2). Discard fluid filter element.

(3) Remove seal (4) from hydraulic oil filter assembly base

(1). Discard seal.

NOTE

Apply lubricating oil to seal prior to

installation.

(4) Install seal (4) on hydraulic oil filter assembly base (2).

(5) Install fluid filter element (3) in hydraulic oil filter

assembly base (2).

(6) Install hydraulic oil filter assembly bowl (1) on filter

assembly base (2) and hand tighten.

19-66

Change 1

Back to Top