TM-9-2320-386-24-1-1 - Page 184 of 1078

TM 9-2320-386-24-1-1

0025 00

0025 00-15

ITEM

NO.

INTERVAL

ITEM TO

CHECK/

SERVICE

EQUIPMENT NOT

READY/AVAILABLE

IF:

PROCEDURE

Table 1. Unit Preventive Maintenance Checks and Services (Contd).

35

Annually

Turbo-

charger

CAUTION

Turbocharger bearing failures can

cause large quantities of oil to enter

the air intake and exhaust systems.

Loss of engine lubricant can result in

serious engine damage.

Do not continue engine operation until

the turbocharger is repaired or

replaced.

a.

Remove exhaust outlet piping and

inlet piping from turbocharger (3)

(WP 0066 00). Inspect turbine wheel and

compressor wheel for contact with

turbocharger housing.

b.

If there is contact, notify direct

support maintenance.

c.

Visually check for oil leaks. Notify

c.

Any class III oil

direct support maintenance if leaking

leakage.

33

Annually

Engine

Inspect engine for accumulated grease and

oil. Remove grease and oil by steam-

cleaning engine.

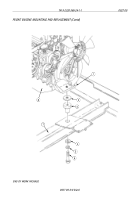

34

Annually

Engine

Inspect engine mounts for damage and

Engine mounts

mounts

loose mounting hardware. If loose, tighten

are damaged or

240 lb-ft (325 N

•

m). Notify direct support

loose.

maintenance if damaged.

NOTE

Perform all semiannual checks listed in

this table.

3

32

Semiannually

Frame and

c.

Check bolted frame connections for

(Contd)

cross-

loose bolts and nuts, tightness, and proper

members

mating with frame surfaces. Check the

torque of all bolts not scheduled to be

removed in accordance with Torque Limits

WP 0385 00

d.

Check welded frame connections for

d.

Any broken or

integrity, deterioration, and flanking.

cracked welds.

Notify direct support maintenance to

replace or repair welded frame connections.

Back to Top