TM-9-2320-440-13-P - Page 478 of 1616

TM 9-2320-440-13&P

0049-2

0049

e.

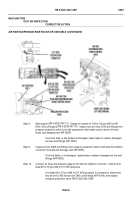

Hydraulic Lines and Fittings.

Look for wear, damage, and leaks;

make sure clamps and fittings are tight.

Wet spots indicate leaks.

Stains around a fitting or connector can mean a leak.

If a leak comes from a loose fitting

or connector, tighten it.

If something is broken or worn out, report it to Field Level Maintenance.

f.

Damage is defined as:

Any conditions that affect safety or would render the vehicle unserviceable for

mission requirements.

LEAKAGE CLASSIFICATION AND DEFINITION.

CAUTION

Equipment operation is allowable with minor leaks (Class I or II). Consideration

must be given to the fluid capacity in the item/system being checked/inspected.

When in doubt, notify the supervisor. When operating with Class I or II leaks,

continue to check fluid levels as required in the PMCS. Class III leaks should be

repaired using tools available if possible. If not, use “Not Fully Mission Capable If”

column criteria.

NOTE

•

If leakage is detected, further investigation is needed to determine the location and cause

of the leak.

If there is any doubt, contact your supervisor or Field Level Maintenance.

•

Diesel engine slobber is an inherent condition of two-cycle diesel engines when engines

are allowed to idle for prolonged periods of time.

This characteristic may be incorrectly

interpreted as a Class III leak.

Check engine oil level.

If there is any doubt, consult your

supervisor or Field Level Maintenance.

a.

Class I.

Leakage of fluid as indicated by wetness or discoloration not great enough to form drops.

b.

Class II.

Leakage of fluid great enough to form drops but not enough to cause drops that fall from item being

checked/inspected.

c.

Class III.

Leakage of fluid great enough to form drops that fall from the item being checked/inspected. Fix

leak using proper tools.

END OF WORK PACKAGE

Back to Top