TM-9-2330-326-14-P - Page 105 of 540

TM 9-2330-326-14&P

6-29

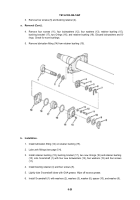

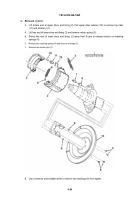

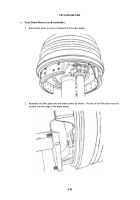

6-9. HUBS AND DRUMS REPLACEMENT.

This Task Covers:

a. Removal

b. Installation

c. Follow-On Tasks

Initial Setup:

Tools and Special Tools:

References:

Tool kit, general mechanic’s (Item 4, Appendix B-3)

Appendix C

Shop equipment auto repair, FM basic (Item 3, Appendix B-3)

Appendix H-22

Torque wrench (Item 8, Appendix B-3)

Appendix H-25

Floor jacks

Appendix H-26

Jack stands

Appendix H-27

Appendix H-28

Equipment Conditions:

Appendix H-30

Landing legs down

Appendix 31

Semitrailer disconnected from prime mover

Appendix H-35

Tires and wheels removed (para. 6-18)

Tires chocked

Ground boards emplaced

WARNING

•

Jack must be positioned directly under axle to prevent

slippage. Direct all personnel to stay clear of vehicle when

vehicle is supported in the air. Failure to do so could result

in serious injury and damage to equipment.

•

To prevent shifting of trailer, floor jack should be used only

on a hard, level surface. Use ground boards (Para-

graph 6-24), if necessary. Chock tires.

NOTE

•

ABS tone ring is part of hub assembly not a separate item of

supply.

•

There are four sets of hub and drums on the M871A3

Semitrailer.

This

procedure

removes

and

installs

one

complete set.

•

Repair, Turning, and Final Disposition of Drums are Direct

Support tasks.

•

Brake drums may be re-bored at Direct Support. Reference

Appendix H-25.

•

For detailed procedures and/or information see referenced

“H” Sections.

Back to Top