TM-9-2330-326-14-P - Page 95 of 540

TM 9-2330-326-14&P

6-19

6-7. SERVICE BRAKES—S-CAMSHAFT REPLACEMENT.

This Task Covers:

a. Removal

b. Installation

c. Follow-On Tasks

Initial Setup:

Tools and Special Tools:

Materials:

Tool kit, general mechanic’s (Item 4, Appendix B-3)

Grease, GAA (Item 6, Appendix F)

Jack stands

References:

Equipment Conditions:

Appendix C

Semitrailer disconnected from prime mover

Appendix H-34

Axles supported by jack stands

Tires and wheels removed (para. 6-18)

Brake drum removed (para. 6-9)

Brake shoes removed (para. 6-8)

WARNING

•

Air brake chambers (all) must be caged before working on the

brake system to prevent serious injury to personnel and damage

to equipment. Wheels must be chocked.

•

The axle must be firmly supported to prevent shifting of the

semitrailer. Shifting may cause serious injury to personnel and

damage to equipment.

CAUTION

Clean and check all S-cam brake components for wear and

damage. Replace worn or damaged parts. At Triennial Service

replace all O-rings, bushings, retainers, snap rings, lockwashers,

and brackets on each axle end.

NOTE

•

There are four brake S-camshafts (two left and two right) and

they are removed and installed the same way. Right and left

does not mean left and/or right side. Left or right S-camshaft is

specific to S-camshaft rotation in operation (see Appendix

H-34). This procedure covers one brake S-camshaft.

•

S-camshafts and related parts are to lubricated in accordance

with Appendix C.

General Procedure:

a. Removal.

1.

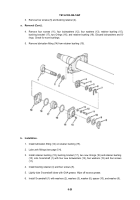

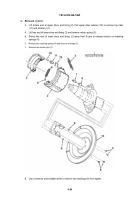

Remove snap ring (7) and retaining ring (8) from S-camshaft (1). Discard retaining ring.

2.

Remove S-camshaft (1), washers (2), washers (3), washer (6), spacer (10), and washer (9) from

bushing retainer (4).

Back to Top