TM-9-2330-331-14-P - Page 127 of 472

TM 9-2330-331-14&P

0019 00

Table 4.

Organizational PMCS - Continued

ITEM

MAN-

ITEM TO BE

EQUIPMENT

NO.

INTERVAL HOUR

CHECKED OR

SERVICED

PROCEDURE

NOT READY/

AVAILABLE IF:

CAUTION

•

Any bumps, valleys, or

warping of the coupler plate

will cause uneven loading of

the fifth wheel, which could

result in damage to the top

plate and poor lock life.

•

The coupler plate should

not bow upward (concave)

more than 1/16 in. (1.58 mm)

within a 19-in. (48.26-cm)

radius from kingpin.

•

The coupler plate should

not bow downward (convex)

more than 1/4 in. (6.35 mm)

within a 19-in. (48.26-cm)

radius from kingpin or more

than 1/8 in. (3.18 mm) at a

10-in (254-mm) radius from

kingpin.

6

Semi-

Annually

.50

Coupler Plate

This should be checked every 6,000

miles or semiannually, whichever period

is shorter.

NOTE

Lubrication is not required if

towing with a M915A3/A4, with

teflon coated coupler plate.

a. Clean coupler plate and kingpin.

Lubricate according to WP 0022 00-4

after checks are completed, if required for

prime mover.

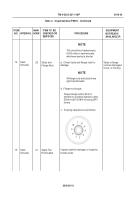

b. Check flatness of coupler plate using

a 48 in. (1.22 m) straight edge. Check

flat edge in all directions.

Straight edge

exceeds .25

(6.35 mm) gap.

0019 00-5

Back to Top