TM-9-2350-311-10 - Page 102 of 775

TM 9-2350-311-10

2-3

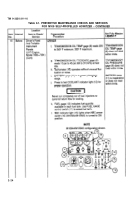

PMCS PROCEDURES - CONTINUED

l

Do not direct a high pressure water hose or steam cleaner against the opening between the

hull and doors or hatches or against exhaust grilles, mufflers, fuel cells, or other electrical

components. Use of a high pressure water hose is only authorized on suspension

components. Failure to heed this caution may result in damage to equipment.

l

After operation in water, mud, and loose sand, the vehicle should be cleaned and lubricated

as soon as possible, without waiting for the next scheduled service.

c.

The “Item to Check/Service” column identifies specific items to be checked or serviced.

d.

The “Procedure” column tells how to do the required checks and services and which crewmember is responsible

for the task. Carefully follow these instructions.

e.

The “Not Fully Mission Capable If" column explains when and why the equipment cannot be used.

2-4 GENERAL CHECKS

While performing PMCS, have tools available and check for the following:

a.

Loose bolts. A loose bolt can be difficult to spot without using a wrench. However, you can often identify loose bolts

by observing loose or chipped paint around bolt head and bare metal or rust at its base. Tighten loose bolts and spot

paint as required.

b.

Damaged welds. Damaged welds may be detected by observing rust or chipped paint where cracks occur.

c.

Frayed electrical wires and loose connectors. Check electrical wiring for cracks due to aging and exposed wires

that could cause an electrical short. Tighten loose clamps and connectors.

d.

Frayed brake cables and loose linkages. Check brake cables for signs of excessive wear near middle of cable.

Ensure throttle and steering linkages are properly secured.

e.

Corrosion. Check for signs of deterioration, rust, unusual cracking, softening, swelling, or breaking.

2-5 LEAKAGE DEFINITIONS

l

Equipment operation is allowable with minor leakages (Class I or II). Of course, you must

consider the fluid capacity in the item/system being checked/inspected. When in doubt,

notify your supervisor. When operating with Class I or Class II leaks, continue to check fluid

levels as required in your PMCS.

l

Class III leaks should be reported to your supervisor or unit maintenance.

Leakage definitions for operator/crew PMCS shall be classified as follows:

a.

Class I. See page of fluid (as indicated by wetness or discoloration) not great enough to form drops.

Change 2 2-17

Back to Top