TM-9-2350-311-20-1 - Page 489 of 1275

TM 9-2350-311-20-1

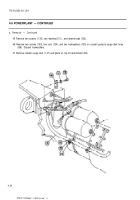

4-5 POWERPLANT — CONTINUED

b. Inspection — Continued

4

5

6

7

8

9

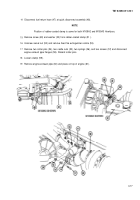

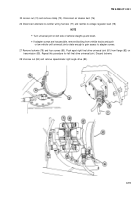

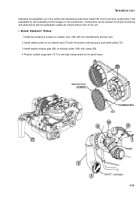

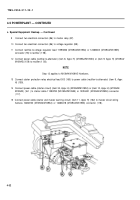

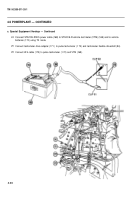

Check oil hoses, tubes (146), and connectors (144) for cracks, leaks, and seepage of oil (para 5-3 and 9-4).

Check for stripped or damaged threads on connectors (147), retaining bolts, nuts, and studs. Repair threads or

replace components/items as appropriate.

Check electrical wires, leads, and connectors (148) for cracked insulation, oil, and grease on cables and

connectors (para 8-41 or 8-42).

Check for broken screws and bolts. Replace broken screws or bolts.

Check for damaged, burred, pitted, or gummed-up seals, gaskets, and preformed packing seats. Clean,

remove burrs, and replace components as required.

Check hull engine compartment floor for pools of oil, fuel, and coolant.

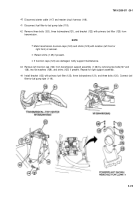

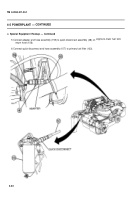

10 Check radiator (1 49) for coolant level. Check coolant for serviceability (para 2-15).

11 Check coolant hoses (150) and tubes for cracks, deterioration, and signs of coolant seepage (para 7-1 and

7-2).

12 Check oil filters (151) and fuel filters (123 and 152) for collection of sediment on filter elements (para 5-4, 6-6,

and 6-7).

4-28

Back to Top