TM-9-2350-311-20-2 - Page 100 of 828

TM 9--2350--311--20--2

2--39

c.

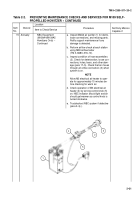

Soldering a Connection

1

Apply flux (item 15, Appx D) to the component. Heat both the wire and the connection point with tip of sol-

dering gun. If wire is insulated, do not melt the insulation.

2

Apply solder (item 34, Appx D) to heated wire/connection point. Let the heated wires and metal components

melt the solder. Don’t glob solder in general area of component and melt it with tip of gun.

3

Apply solder sparingly. You have enough solder when the tip and the connection are completely wet.

4

Allow the connection to harden before touching. When dry, the connection will be smooth and bright.

d. Checking a Connection

1

If solder and connection look grainy, the connection is a poor one. Use gun to reheat connection if soldered

joint does not look smooth and bright.

2

Check for a cold solder joint. If end of wire or component connection are mobile, a cold joint has been sol-

dered. Reheat the connection and make sure both the lead and the component are heated sufficiently this

time. If needed, apply a small amount of additional solder to get a good connection.

3

Immediately upon completing soldering, inspect area surrounding soldered connection. Check for solder

“bridges” between the component you wanted to solder and components you do not want to solder. Make

sure the solder you applied touches only the connection you intended to solder. Desolder and clean away

any unintended bridges using hot soldering iron and dry cloth.

2--17 APPLICATION OF ADHESIVES

WARNING

Adhesives and solvents can burn easily, can give off harmful vapors, and are harmful to skin and

clothing. To avoid injury or death, keep away from open fire and use in well-ventilated area. If adhe-

sive or solvent gets on skin or clothing, wash immediately with soap and water.

CAUTION

Donotattempttopullorpryoneitherbondedsurfaceafter mating.Damagetosurfaces couldresult.

a. Clean surface to be bonded. Surface must be free of grease, paint, talc, rust, soapstone, or any foreign substance.

b. Stir adhesive unit fluid. Apply an even coat of adhesive to each mating surface. Let dry until tacky (about 20 minutes).

Temperature and humidity will affect drying time.

c.

Apply another coat of adhesive to both previously coated surfaces. Let dry until tacky (about 20 minutes). Adhesive is

the right consistency when it will not transfer to finger when touched lightly.

d. Press mating surfaces together. Use a rubber roller or other suitable tool to ensure full contact between surfaces.

Back to Top