TM-9-2350-311-20-2 - Page 82 of 828

TM 9--2350--311--20--2

Change 4

2--21

2--9

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

2--9.1

General

Preventive maintenance is the step-by-step caring, inspecting, and servicing of equipment to maintain it in good condition

and to locate problems before extensive and time-consuming repairs or replacements are needed. Refer to DA PAM

750--8 for instructions on use of forms for preventive maintenance services.

This section has the procedures and instructions needed to perform unit preventive maintenance checks and services.

These services are done by unit maintenance personnel with the help of the vehicle crew.

2--9.2

Explanation of Preventive Maintenance Checks and Services, Table 2--1, Columns

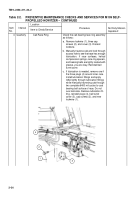

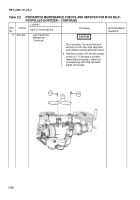

a. The “Item No.” column provides the number to be used by the mechanic when recording all faults found and actions

taken on DA Form 2404, Equipment Inspection and Maintenance Worksheet. The item number on the DA Form 2404

must correspond to the item number of the preventive maintenance check.

b. The “Interval” column provides the interval at which preventive maintenance checks and services are to be performed

by unit maintenance. The intervals are determined by whichever comes first: quarterly; annually; or 750 miles or 75

hours. This is scheduled on DD Form 314 in accordance with DA PAM 750--8.

After operation in water, mud, and loose sand, the vehicle should be cleaned and lubricated as soon as possible, with-

out waiting for the next scheduled service.

c.

The “Item to Check/Service” column identifies specific items to be checked or serviced.

d. The “Procedure” column tells how to do required checks and services. Carefully follow these instructions.

TM 9--2350--311--10 contains maintenance instructions which the unit mechanic must use to perform the specified

duties.

Unit maintenance is defined by, and limited to the following general procedures. Approval to perform higher category

services must be given by the supporting maintenance unit.

1

ADJUST. Make all needed adjustments using instructions in this manual and/or technical bulletins.

2

CLEAN. Clean the unit to remove old lubricant, dirt, and other foreign matter. Special cleaning instructions

are given as needed.

3

LUBRICATION. Lubrication applies to lubrication operations which should be done at the prescribed time

intervals or usage.

4

TIGHTEN. All tightening operations should be done according to specified torque readings where noted in

this manual. When torque is not specified, care should be taken not to strip or distort threads by overtighten-

ing. Use a torque-indicating wrench where specified. Tightening includes the correct installation of lock-

washer, nut, lockwire, or cotter pin needed to secure the tightened nut or bolt in place.

5

REPAIR. Restore an item to a serviceable condition. This includes, but is not limited to inspection, cleaning,

preserving, adjusting, replacing, welding, riveting, and strengthening. Refer to Appendix B for authorized

crew and unit maintenance level repair, replace, and adjusting functions.

e. The “Not Fully Mission Capable if” column explains when and why the equipment cannot be used.

Back to Top