TM-9-2350-358-BD - Page 26 of 343

TM 9-2350-358-BD

2-5.

ASSESSMENT PROCEDURE - CONTINUED

d.

Each repair:

(1)

Contains general information about the problem.

(2)

Lists materials and/or tools required other than those commonly available to the crew, MT, and MST (if

the items listed are not available, improvise.

Anything that will do the job is acceptable).

(3)

Lists the estimated number of soldiers needed and the estimated time required to complete the repair.

(4)

States the operational limitations caused by the repair action before experiencing further

damage/degradation to the howitzer.

(5)

Provides other options you can use depending on the availability of personnel, materials, tools, and/or

time (this does not include standard maintenance procedures or recovery).

e.

Additional data is contained in the appendixes.

(1)

Appendix A lists Referenced Publications used for repair of the M109A6 howitzer.

(2)

Appendix B lists Special or Fabricated Tools.

(3)

Appendix C lists Expendable/Durable Supplies and Materials.

(4)

Appendix D lists Substitute Materials/Parts.

(5)

Appendix E lists BDAR Fixes Authorized for Training.

f.

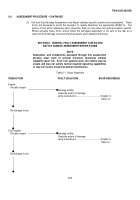

As an example, presume that the engine coolant is overheating, only at high engine speeds.

There is no

apparent damage to the cooling system and fluid is present BDAR assessment procedures function as follows:

(1)

General Fault Assessment Table 2-1 directs the reader to visually inspect each major system of the

howitzer.

The reader inspects the engine and fuel system before determining that there is damage in the cooling system.

The reader is referred to Table 6-1 to perform a visual inspection of the coolant subsystems for which BDAR fixes are

available.

Damage to the coolant hose is found, affecting the water pump.

The reader must determine whether the

damage is repairable by assessing resources available and listed in the repair procedure paragraph (para 6-12).

If

damage cannot be repaired, the reader is directed to note repair requirements and recover the howitzer.

The assessment

would then be complete.

Assuming repair is possible, however, the reader would note repair requirements, complete

visual inspection of coolant subsystems (Table 6-1), and return to Table 2-1 to complete visual inspection of the howitzer’s

major subsystems.

Once all major subsystems have been visually inspected, the reader is directed to perform all noted

repair requirements and begin operation observation (Table 2-2).

(2)

General Fault Assessment Table 2-2 directs the reader to damage affecting operation of major systems,

subsystems, and components in the same way as the visual inspection.

If recovery becomes necessary, the assessment

ends.

If not, repair requirements are noted and performed only after the howitzer operation of all major systems have

been observed

In this example, restored water pressure is observed following repair of the collapsed hose.

The reader is

then directed to perform all final damage assessment, (Table 2-3).

(3)

General Fault Assessment Table 2-3 directs the reader to evaluate the howitzer’s performance

capability.

In order to determine its mission readiness.

The performance of the howitzer in this example is evaluated to be

near normal, so the howitzer is either FMC or combat capable.

All damage assessment is complete and this howitzer is

ready for use at the commander’s direction.

g.

At any point on each of the assessment levels, the assessor can abort the procedure and direct

recovery/evacuation or other actions if the tactical situation dictates.

2-3

TM 9-2350-358-BD

Back to Top