TM-9-2520-254-34 - Page 47 of 126

CHAPTER 4

TROUBLESHOOTING

4-1. Purpose and General Instructions

NOTE

Information in this chapter is for use of

Ordnance maintenance personnel, in

conjunction with and as a supplement to

the troubleshooting section of end item

organization manual. It provides con-

tinuation of instruction where a remedy in

the organizational maintenance manual

refers to Ordnance maintenance personnel

for corrective action.

a.

Operation of a deadlined vehicle without a

preliminary examination can cause further damage

to a component and possible injury to personnel. By

careful inspection

and

troubleshooting,

such

damage and injury can be avoided. In addition, the

cause of faulty operation of a vehicle or component

can

often be determined without extensive

disassembly.

NOTE

This chapter contains inspection and

troubleshooting procedures to be per-

formed while a disabled component is still

mounted in the vehicle as well as after it

has been removed.

b.

The inspections made while the component is

mounted in the vehicle are, for the most part, visual

and are to be performed before attempting to

operate the vehicle. The object of these inspections

is to determine the condition of the component and,

if found defective, to take precautions to prevent

further damage.

c. The troubleshooting performed while the

component is mounted in the vehicle is that which

is beyond the normal scope of the using

organization. Check the troubleshooting section of

end item organizational manual, then proceed as

outlined in this chapter.

d.

If the component alone is received by the

Ordnance establishment, inspection should be

performed to verify the diagnosis made when the

component was in the vehicle. This inspection, to

uncover further defects, or to determine malfunc-

tions, is particularly important because it is often

the only means of determining the malfunction

without complete disassembly of the component.

4-2. Operating Characteristics

To perform effective troubleshooting, the mechanic

must have a thorough knowledge of—

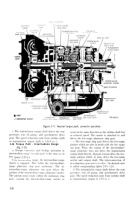

a. Construction Features.

Refer to paragraphs 2-

1 through 2-11 for description and function of the

transmission components.

b.

Functions

of Components.

Refer to

paragraphs 2-12 through 2-26 for explanations of

hydraulic operations and power flow through the

transmission components.

c. Operating Instructions.

Refer to end item

operator’s manual for instructions on operating the

transmission while driving the vehicle in which it is

installed.

d. Oil Supply.

Refer to paragraph 1-6 for oil

supply information.

e. Adjustments.

Refer to paragraph 5-63 for

adjustment procedures.

f. Oil Pressures.

Refer to table 1-1, paragraph 1-

7, for oil pressures.

4-3. Troubleshooting—Before Removal or Op-

eration

a.

Do not operate the vehicle prior to completing

the procedures described in this paragraph. Refer

to paragraph 4-1 for the purpose of these in-

spections.

Inspect for oil leakage.

Visually inspect

all split-lines, connections, covers, output shaft, and

plugs for oil leaks. Oil leakage at split-lines may be

caused by loose bolts or defective gaskets. Tighten

bolts where leakage is found. If leaks continue,

install new gaskets.

NOTE

Inspect transmission again for oil leakage

after starting vehicle engine (para 4-4).

b.

Inspect transmission assembly for loose

components and loose, disconnected, or damaged

linkage. Check linkage and operator’s controls for

damage, wear, binding, or improper adjustment.

Proper adjustment and operation of shift and

throttle control linkage are essential to efficient

performance of the transmission.

4-4. Troubleshooting—Before Removal and

During Operation

a. General.

If the inspections in paragraph 4-3 do

not reveal the cause of failure, and the vehicle is

operable, further troubleshooting is necessary. Do

not remove the transmission from the vehicle until

the causes of trouble listed in table 4-1 are checked.

Refer to paragraph 4-3 for the purposes and scope

of these troubleshooting procedures. To make a

thorough check of transmission performance, be

sure the vehicle engine is properly tuned and that

the transmission oil level is correct (para 1-6).

Inspect again for oil leaks after starting engine.

b. Troubleshooting

Table.

This condensed

troubleshooting information will assist mechanics

in diagnosing and correcting malfunctions in the

4-1

Back to Top