TM-9-2520-270-34 - Page 388 of 933

TM 9-2520-270-34

REPAIR DISCONNECT CLUTCH ASSEMBLY

This task covers: Disassemble (page 4-82). Assemble (page 4-87).

INITIAL SETUP

Tools:

Arbor press – (Item 3, App C)

Bearing installer — (Item 6, App C)

General mechanic’s tool kit:

automotive – (Item 33, App C)

Industrial goggles — (Item 39, App C)

Inserted hammer face holder —

(Item 39A, App C)

Inserted hammer face – (Item 39B, App C)

Inserted hammer face – (Item 39C, App C)

Leather gloves – (Item 42, App C)

Micrometer caliper set —

(Item 52, App C)

Socket wrench attachment —

(Item 79, App C)

Socket wrench set – (Item 89, App C)

Telescoping gage set — (Item 93, App C)

Thermal drying over — ( Item 94, App C)

Torque wrench — (Item 99, App C)

Torque wrench – (Item 100, App C)

Wire-twister pliers —

(Item 107, App C)

Compressed air source, filtered, 30 psi

(207 kPa) maximum

Materials/Parts:

Dry ice – (Item 4, App B)

Lockwire – (Item 5, App B)

Sealant compound – (Item 11, App B)

Transmission oil – (Item 12, App B)

wood block (2) — (Item 3, App D)

Wood blocks (2) – (Item 4, App D)

Bushing

Preformed packing

Preformed packing

Preformed packing

Personnel Required:

Track Veh Rep 63H10

Helper (H)

References:

TM 9-214

Equipment Conditions:

Disconnect clutch assembly on workbench.

See page 4-78.

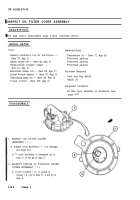

WARNING

Compressed air can injure you

and others. Do not aim air at

soldiers. Do not use more

pressure than 30 psi (207 kPa)

Always wear goggles.

1. REPAIRER AND HELPER SEPARATE

CLUTCH PISTON (1) FROM PISTON

DISCONNECT CLUTCH HOUSING (2).

a. Loosen piston (1) from housing (2) by

applying air pressure to oil Pens (3) in

bushing (4).

b. Helper hold housing (2) and apply air

pressure to oil ports (3) in bushing (4).

Repairer, using two pliers, remove

piston (1) evenly.

4-82

Change 3

DISASSEMBLE

DESCRIPTION

Back to Top