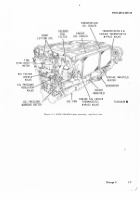

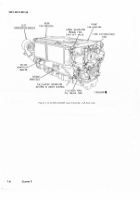

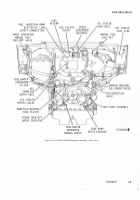

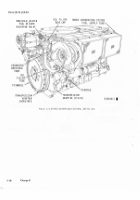

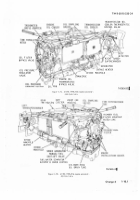

TM-9-2815-220-34 - Page 33 of 532

lined, steel-backed, spLIT bushing TyPe bear±Ng is

pressed ±nTo the pis²on pIn end of The rod. ³he

rep´aceaB´e pµ'ecisIon connecTing Rod BearinGs are

The stee´¶backed, sp´±T type hav±ng copper¶´ead

alloY bear±ng suRfaces.

1-±2.

PistonS, PiNs and RINgs

³He pIstons

(47,

Fig·

²³8)

are a´uminuM casTings,

caM g¸ound and Tapered To provide aN accuRaTe ¹ºT

±N The cyl±ndeRs aT oPeraTiNg teMperatures» ³he

pis¼on doMe Is machIned To The shape of a conica´

sec½Ion (ToRIDa´ Shape) so ThaT I² TaPeRs ±nTo the

open Type coMbusTion chambeR¾ Each p±sTon is ¿ÀtÁ

Ted wÂTh four RIngÃÄ ³he Top riÅg gRoove Is coMÆ

poseD oF a s²ee´ InsÇRT Which Is an InTegral paÈt oF

Éhe pisTon¾ Êhe ThRee RemainIng RIng gRooves Are

machiÅed inTo THe alumInum piËToNÌ Íhe upper

three Rings are coMpress±on r±NgÎ and the boÏÐoM

Ring is an oI´ÑconTRo´ RIngÒ ³he heavy Óa´´ed, TubuÔ

´ar, ÃTee´ PisTon pIns aRe

f

ÕÖ×FØoaTÙng In the PisTon

and The connecTIng rodÌ Úhe pisTon pin is reTa±Ned

in the pisTon by reta±ning ¸ingÛÜ one aT each end of

THe PIston pinÝ In The p±sTon pin BoreÞ

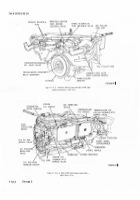

1´±3µ

CylInDers aND VaLveS

NOTE

the k¶y numb¶rs sHown B¶low in

Pßàená

·

h

eSes ReF¸¹ ·º FIgU»e ¼½¾ ¿xcÀpÁ w

H

»Ã

OâHãäÓiåæ indiCçèédê

a.

Each cyliNder assemb´y is an iÅd±vidua´ly reÆ

P´aceab´e unIt thaT cons±sTs of a baëRe´ì coo´ing fin

mu¿fí and a cy´Inder Head. ³he cylIndeR barre´Ý

dome and inTake and exhausT poRT ´ineRs aRe stee´î

³he aluMinuM cylinder head coo´iNg ïºns are cast

to the sTee´ domeð ³he coo´Ing fins fñr The barrel are

machined into an a´umINum mufF aNd shònk onTo

The sTee´ ba¸reóô õfter the cy´±nder barre´ önÛ are

MachInedì The head and barre´ aRe e´ecTron beaM

Óe´ded to ÷oRm a single uűTô Va´ve gu±des and

seats are sHrunk inTo p´ace in THe headÞ õ mountø

ing f´aNge is maChined on the cy´indeR barRel near

the base To provide an atTachment of The cy´±NdeR

to the crankcaseù ³he cyl±Åder aÛseMbly is secured

to The crankcase Óith sTuds aNd NuTsú õN ouTer

eXtensIon oF the cy´inder Head enc´oÛes a recesÛ or

rocker boXì ÓhIch houses The valves, va´ve sP¸±nGsí

and related ParTsð ûocker arM asÛeMblies ü1and 2ý

are held In P´ace by rocker shafTs ±n the cyl±nder

Head va´ve rocker suppor¼ coverþ

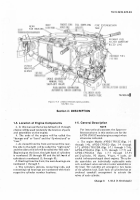

ÄÅ

õ caMshaft bear±ng surface is Provided iN each

cyl±Nder· ³he caMshaft beariÅg ±s bored ÿĀth the

cy´±Nder head va´ve rocker supPorT cover ±n P´ace;

thereForeā The covers are not ±nterchaÅgeab´e and

eacH Must remaIn as a Part of a sPec±¿±c cy´±nder

asseMblyú Each cy´iÅder has reP´aceable camÛhaft

beaĂăngÎ aT tHe caMshaFt bore· ĄdenT±fyinG nuMą

ÆM 9ÇÈÉÊ5ËÈÈ0ÇÌÍ

bers are used on cy´±nder aNd coverÛ to PreveÅt

M±smatch±ngÞ ĆounTerbores ±n tHe rocker boX and

Rocker supporT covers accomModate The iNtercyÔ

´IndeR Rubber hoses and The stee´ Flanges Óhich

enc´ose the camshaft betÓeen the cćl±ndersÌ

c.

Úhe stem of the ±nTake valve

ÎÏ0Ð

and eXhaust

va´ve

ÑÒÓÔÕ

fĈr each cy´inderí eXTeĉds into The

rocker boX. ³hRee nesTed spëÙNgÛÜ coĊpressed beÆ

TÓeeN TÓo reTa±ners and secuRed To tċe valve sTeM

by tÓo cone×shaped locks, ho´d each va´ve to its

seaT» Each eXhausT va´ve has a posiTive valve

RoTaToR ÓČčich a´so serves as The ´oÓer sprIng reÆ

taIneRĎ ďa´ve c´eaRance adjusT±ng screÓs ÿĐTh fØaT

sÿÂve´ pusher pads are Mounted on one end of The

va´đe RoĒkeR arMs

Ö×

and

ØÙÚ

dÛ

ēorged sTee´ vĔ´ve rocker aĕĖs ė1 and

ØÙ

ÓiTh

ro´´er cam-¿o´loĘeRs arę useĚ´· Íhe ro´´eRs are harÆ

dened and honed Ïo Proě±de aN exTreMely ÛMooth

and PermanenT conTacT sURĜaceþ ĝoĞ´oÓ Rocker arM

shaFTs and dğĠl´ed passages in The RocKer arms conġ

vey o±´ to a´´ mov±ng Parts¾

ÜÝÞßà

CAmshafts

áâÆã

ähe KeY åUæçeRS

åHOÓn

èéLêW ëì

P

a»¶í

-

I

îï¶s¶s r¶ð¶r ñò óiGôr¶ õö÷ø

A±

³he Left and r±ght camshafT asseMblies

ùú

and

10) are mounTedí one on each bankì oÅ The cy´IndeRs

and operate the va´ve MechaN±sM» Úhe camshafts

aRe hol´oÓ to ProvIde o±´ Passages for Pressure ´ubĢ

ricaTion to THe valve PaRTs and to PerM±T deģect±oÅ

Óhen The cy´indeRs ïºre· Íubu´ar Ĥo´ded rubber

hoses enc´ose The camshafTs beTÓeeN cY´indersþ

ûü

Each camshafT ±s dRÀven by The accesso¸y drÀve

gear ü12), accessory dr±ve gearshaft asseMbly

ýþÿĀ

caMshafT drive beve´ gearshaft

āĂă

camshaĜT d¸±ve

gearshafT

ĄąĆć

and caMshafT dRIven gear

ĈĉĊ

THrough

aN incl±ned quil´ Type camshaĥ d¸Àve shaft

ċ6Čč

Úhe

dĦħve shafts caÅ be reMoved to PerMit ÛeParate

roTatioN of The camshafTs ïĨR engine tiMingô ĩhen

camshafts aRe correcTly Positioned in re´at±on to

The crankshaftĪ the dRive shafts have d±¿¿erent

ÅuMber of sp´ines oN each eÅd and th±s alloÓs theM

to be inÛe¸ted ±n the caMshaft beve´ gearÛHafts

ÓithouT dIsTurbing re´at±onshIP īetÓeen caMĬ

sHafts and craNkshafT·

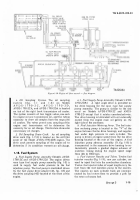

1-Ďď.

±ub²icatiON ³YsteM

ĭögsĎ

²ĐÓ

and

²đ²Ē)

a±

ēĔĕĔĖAė

³he Ma±n pressure o±´ PuMP draÓs oil

froM the Pressure o±l PuMP coMPartMeÅt ÀÅ the oil

Pan· ÚhIs coMPartMeNt ±s fed by the scaveÅge o±l

Pump Óhich picks uP oi´ ¿Rom the f¸ont eÅd oĜ the

o±´ pan and by oi´ Óhich dra±nÛ Ànto the presÛure

coMPartM

e

n

Į

t from the cover oĜ the Pressure PuMp

coMPa¸tMent and The reserve coMPartMeNtþ ³he

įhaÅİe

Ę

ęĚěĜ

Back to Top