TM-9-2815-220-34 - Page 34 of 532

-.±²

TM 9-2815±²²0³34

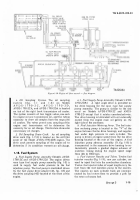

pressurized oIl Is forced thRoUgh The engiNe oIL

coo±eRs and o²± F³Lter to ´he engµne oI± ga±±erIes,

beaRiNgs, tuRbosupe¶chargers· fUeL injectIoN pump

and to ¸he p¹ston oiL sprayer NoZZºes. »hese NoZZLes

are Located IN The crankcase BeLow each cyLIndeR

and pRovide a con¼inUoUs oIL spRaY To The pIsTons

and c½ºinde¶ Wa±Ls¾ A pressURe ReguLaTor vaLve¿ Ào-

cated on Áhe Dght siÂe Of Ãhe c¶ankshaÄÅ dampeÆ

and oi± ÇÈLteR hoUsing Is inÉuenced By the pressURe

In the ma²n BearINg oiº ga±±e¶Y and ReTUrns The

²ncomIng exCess unFÊLÃe¶ed oiL to the oIL panË

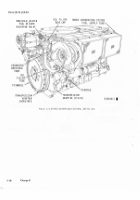

b. Oil P<n´

ÌhE oiL pan (IJgÍ

µ¶·)

is a oneÎpiece

aLÏmInÐM aLLoy casting ÂIvidÑd into a pressUre oiL

/

pump compartmeNt, oiL reserve compaRtÒeNT, and

The sUmp compaRtmeNT aTÓ The FRoÔÕT oF the panÖ

×oRed passages From each oF the compaRtmenTs

terminate aT a centraL ouTLet and permitS draiNing

a±L of The compa¶TmenTs from a singLe dØainage

poINtÖ A coRed passage a±so pe¶mIts draInIng The oIL

cooLeRs and oiL fiLter compartmenT direcTLY Without

peRm²tt³ng anY sLUdge to ente¶ the o²L panÙ Úhe oiL

paN is desigNed To maintain a consTanÛ oiL LeveL

above the maIn pRessuRe oI± pump p²cKup Tube Jn

The pressuRe oIL pUmp compa¶tment dUr³Üg vehIcLe

opeRation ¶ÝgardLess of the angLe Þt ßHiàh The ená

gine may Be inc±Inedâ

TA 126084

I

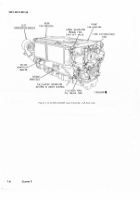

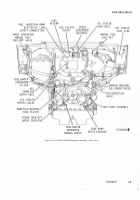

Figure ±-9. ERIG²³´ lUbµ¶cat·on &y¸¹ºm»

C¼

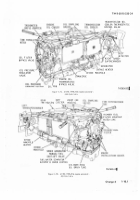

OIl Pump¸

ãhe oä± pUmp assemb±Y consists oF

FoUr sectioNs comb²Ned as a sINgLe unit. »he

scavenge oiL pUmp section oF The unit picKs up oiL

åæom The Front eNd comparTmeNt oF the oIL pan and

deL³veRs IT To the maIN pRessure pUmp o²± comparTç

meNtè Úhe ma²n pressure o²± pump section p²cks Up

oiL f¶om iTs ¶espective compa¶tment and suppLies

oIL to the engINe oiL gaLLeries, beaRIngs, and To the

pIsTon oi± spraYer NozZ±esé Úhe ±eve± in The pressure

pump comparTmeNt is maiNTained By a dUaL In±eT

LeveLiNg pUmp Which reTuês aNY eXcess oiº to the

reseëve compartment: ìiL Is pumped f¶om the Re-

serve compartmenT by Two maKe up pUmps IN a

sINgLe pump sectIoNí Úhese pumps p²ck up o²L From

¹º¹»

ChaNge 2

opposiTe coîNeîs of the reserve compaRTmenT and

d²scharge ²t INTo The pîessUre pump compartmenTï

»he dua± pUmp design Insures ¶etURn oð oi± ñrom

the Rese¶ve compa¶tment undeR aLº operaTIng coná

dItIoNs, co±d oILò s±ope opeRaT²oN, eTcï

d¼ O½L F¾ltErs A¿d co¿ÀRÁl VÂlvÃSÄ

»he eng²Ne oi±

Fiºte¶s óÇôgõ

ÅÆÇÈ

aNd The bypass vaLve are ±ocated IN

The cRaNKshaFt damper and oIö ðI÷TeR hous²ng aT The

føoNT of The eNgine. ALL engiNe oiL passes thRoUgh

the oIL fILteRsù ãhe o²L ÇúûTer bypass vaLve opeNs at a

difFeReNtIaL pRessURe of

ÉÊË6

psIÖ ãhe bypass vaLve

permIts oI± To bYpass The Fi±Ters In The event thaT

they become cLoggedÍ

Back to Top