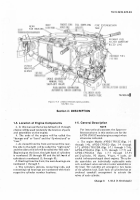

TM-9-2815-220-34 - Page 31 of 532

b.

The EnginE featurEs a Fuel Injec±Ion system

and a ±UrbosUpErcharGED a²r ²nDuctIon system

wh²Ch oB±a²ns oP±²mum En³´nE µErfoRmanc.

¶h

E

·

fuEl InjEc±²on system has a FuEl ²nJEct²on me±er²nG

¸ump whIch supPlIes mEteReD Fuel to InDIv²Dual

cyl²nDErS ±hroUGh ¹ºel ²nJec±oR nozZlEs» ¶he fuEl

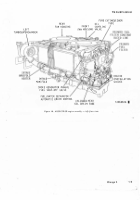

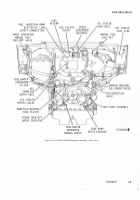

suµply p¼mp assEm½ly (¾¿GÀ 1-3) loca±ED a± thE ¾ront

of ±hE enG²nE Draws fuEL ±hrouGh ±he pR²maRy anD

sEconDaRy FuEL sys±Ems From thE VEh²cle fuEl tanks

anÁ DEl²\•Ers ²t to thE ²nJEc±Ion pUmpÂ

A

±urÃ

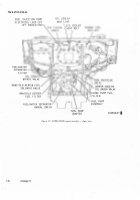

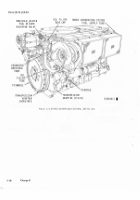

bosupERcharGer assEmbly (¾²GsÀ

1-±

anD

1²2)

²s loÃ

ca±ED On each s²DE oF the EnGÄne a± the REar. 'ÅhE

tÆrbÇsupErcharGErs arE ExhaustÈGas ÁÉÄÊEn anD

²ncrEasE ±he a²ËÌ ¾Íow prEssuRe EnteÎInG ±he a²r InÃ

±aKe man²FÏlDs (ÐÑGsÒ 1ÈÓ aND 1-2)Ô

I

c.

T

h

e

Model

AVDS-1790±2C and

modEL

² vDS³´ µ¶0·2C² engiNes ¸re

EquI¸¸ÕD w²Öh

¸

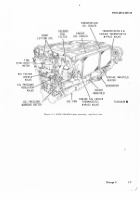

28¹ºo´t oiJ coo´ed dcgener¸toR (fIg. »¹1) c¸p¼blE of

650 ¸½per¾ ouTput o¿ER UÀe EngÁÂE opER¸TÃng

R¸ngÄÅ Æhe gEneR¸toR pRoduceÇ ¸n ¸´tEȸtÉÂg

cÊrËeNt

whIcH ²

Ç

×ØcÖIFÙØD wI±hIn ±hÚ

ÌnÃT To gÁ¿e ¸

diRect cÌÍEnT To t1Îe output teRÏin¸´ÇÐ

I

d³

Ûh

e

ÑoÒels

AÓD

S¹ÔÕ90-2Ö

²vDS¹lÕ90×2DØ ¸Âd ²ÓÙS¹ÚÕ90×2D²

E

ngi

n

e

¸Re equÃpped

wIth

¸ 28

ÊÜlÖ,

300 ¸ÏpeRe ¸iRÛcoo´ed

dÃÜect cÌÝentgeNER¸torÞfÃgÇÅ

ÝÈ5Þ

ÚßàÐl,¸Nd á·àâ8ãÅ

A

bloweR ½oToR ½ountEd on thE genEä¸toR dR¸ws

cooling

a²ß

FRo½ the cREw åo½p¸RtæEnt

Ö

hro

u

g

h

tHe ¸ÃÜ inT¸ke tubE wçècH exTendÇ ¸´ong the

cr¸NKc¸Çe Be´oW THE iNT¸Ke ½¸nIéoLd o THe rÃGêT

side oF tHE

ànáÄnâã

ëhe gEneR¸toR ¸iì eXh¸usí tube

Ä´bow

Iä

coînEcTEd to the Re¸R oé tHE EnginE

ÇhRoudï ðeneR¸toR outlet ¸iR iÇ EñH¸òÇtEd

åhæÜuçh

ÖhØ

rE¸r cooLÃng ón º¸ne.

e.

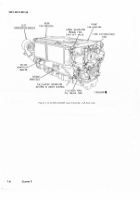

¶hE enènEs have a é4ÈÊol± solEno²D opErateD

s±arter (êGë 1-é)Ô

a

Low vol±aGE sens²nG moDule PReÃ

Êents star±eìí ac±Iva±²on Wîth ²mProPErly charGeD

battEr²Esã

f

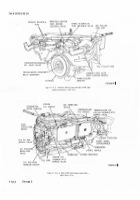

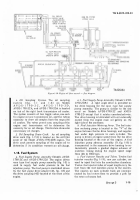

¶hE EnGïnes are lubrIcatED by a fðrcED FeED

systEm. ñhE system cons²sts of ¾ouR c²Ròu²±s; ²Àeóô

±hE scaVEnGE c²RcuI±õ thE maIn or µREssURE o²l c²rö

cuItÞ the leveݲnG cIrcu²tô a÷øD thE make u¸ c²rcuI±ù

¶hEsE c²RcuI±s arE opErateD InDEpenDentLy by one

o²l pumP wh²ch cons²sts of FúuR sEpaRaûe sec±²onsó

g±

¶he ünýïnes aRþ EQu²PpeD ÿĀth two ²n±aKE

man²FoLD hEaters (FāGs» 1Ăă anD 㥹) whIch aRE ²nÃ

s±aLÝeD In thE a²R Intake sys±ems bEtween thE InÃ

take man²folD elBows anD thE ±urBosuPerchaRGĆrsć

¶hE heatErsõ whEn opErĈ±eDĉ pReheat ±he a²Î EnteRÃ

InG the cylInDers to facIÝItate colD Ċċa±hER staR±²nG

anD colD wEathEr IDLČ oPERatIonÂ

h´

¶hE Enčne cranKcasE ²s ÊEntED By an EnclosĎD

crankcasE bReďther system wh²ch ²s Êen±eD

±hRouGh thE cÉanKcasE bREather ±ubE ĐfÄGć 1đĒ) at

±hē leFt tuRbosu¸erchaRGeR eXhauĔt PIpeĕ

iµ

¶hE enG²nE Pr²maRy anD fuel/wa±Er seµaRa±oR

typE sEconDary FuEL ¾¿lteRs (êĖsė ĘęĚ anD

l

-ě) bo±h

ÛM

9¶·8¸5¹ºº0¶34

have toP mounteD blEEDeR ÊalÊEs

ôo

assIst ²n ±hE

REmoVal of a²r ¾rom ±he fuEl systemÀ ĜatEr Is rEĝ

movED au±oma±²cally By a constan± bLEeD or²fĞcE ²n

thE pr²mary FuEl ğltEr anD an au±oma±²c wa±Er

DraIn ²n ±hE fueLĠwatEr seParator ġĞL±ERĢ

»¼7½

Accessories

ģEfeR

±

o apPenD²X

a

for ²nFðrma±²on on enG²nE acĝ

cessoĤEsÂ

»¾¿À

CRank±²se

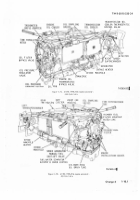

¶hE cRanKcasE (¾¿GĢ

±Á1)

²s a onEĥP²Ece alumInum

castInG w²th foRGEÁ alumInum ma²n bEar²nG caµsć

¶he bEaR²nG caps functIon as an IntEGral part oF

±he cranKcaseć Ħach

õ¸p

²s securED on stuDs ħĨĩh

four slo±±ED nu±sĪ īÅwo thRouGh bðl±s clamp thE

maIn beaĬ²nG caP ²n ±he ±unnEL slo± of the cranKĭ

ĮasEį İIıh IJh²s ±YPE of crankcasE anD bEar²nG cap

cons±Ruct²onij unIfúRm loaD D²stRIbutIon In the bearĴ

²nG arEa ²s obta²nED maK²nG µoss²blE un²ġðRm D²sĴ

±r²but²on of combus±²on ¾orcEs ovEr thE ent²RE

cRankcaseĵ

» ÂÃÄ

MaiN Bea³I´gs

ĶhE seķEn rePlacEablE ma²n bear²nGs aRe thE

s±eelĸbackEDõ sPlIt typE, haÊInG co¸Per-lEaD alLoy

bEaRInG surfacesã ¶he cEntER ma²n bEarInG Is

DouBlEĹ¾ĺanĻED w²th bEar²nG ma±eļ²al ±o control

crankshaft EnD play anD thRustĽ

»ÅÆÇÈ

CRaNKshaft, FlywhEEL, and DampEµ

NOtE

'öe key nu½bERÇ s÷own bEloø

²n

p¸ùeÂú

I

tHEseÇ REF ER to éûguRe 1±8ü

C²

ľĿían ks haFt assEmbLy ĐŀŁł Is a nItŃńĞDED s±eEL

forg²nG w²±h seķen ma²n bear²nG JoUrnaŅs anD s²X

crankp²nsņ Ħach cRanKp²n accommoDa±Es two oµŇ

posInG connect²nG RoD assEmbl²Es (ŀ6)Â ňlanGEs aRE

ProVIDED on ±he crankshaF± FoR mountInG thE

ʼnywheel (Ŋě) on ±he rEar enD anD a ŋors²onal ʲbRaĴ

t²on DampER Ō<ōŎ) on ±hE Fļont enDŏ

BÉ ÊJJ

c

r

N

kp

²n

ýe¸þÿng jouĀ¸´s ¸Re Holloø to

āEduce øeÃgHTÐ Ăo´eÇ ¸re drÃlLed døgo¸´lY THroÌgH

e¸ch ½¸in ýe¸RiNg ăouĄ¸´ ¸nd eñteÂd through tHe

cR¸Âk ąheek

¸nd crankpÃn to pRo¿ide ¸ direcĆ

p¸ÇǸgE

fr

oil under pReÇÇuRe

±o Öh

E connEcting

rod ¸Nd cr¸NKÇH¸éT

maIŐ

ýe¸RÃćĈgs ¸s ÇHoøN ÃN

éÁgòre 1ĉ¶Ċ

c±

ÛőE cRanKshaf± anD FlywhEEÝ aRe statIcally anD

Dynam²calÍy balanceDÀ

DË

¶hE torsIonal ÊIbra±Ion Dam¸ER ŒŀœŔ ²s a prEc²Ã

s²on ʲscous ±yPE anD ²s replacEablE onLy as an

assemblyĢ

»¾Æ»À

Connect¶´g ·ods aNd B¸aRi´gs

¶he connecÖInG roD asŕEmbĺIes Đŀ6, FIGÒ 1-8ł are taŖ

pEreDô ŗÈbeam sect²on steel forŘînGsĢ

a

bronřEŚ

śŜAnŝE

Ì

ÍÎÍÍ

Back to Top