TM-9-2910-226-34 - Page 22 of 208

TM 9-2910-226-34

arrangement. The camshaft also includes gearing for

the distribution function. The fuel injection pump

contains a single-plunger, multioutlet hydraulic

head assembly and is designed to be driven at

crankshaft speed on four-cycle engines.

b.

The purpose of the fuel injection pump is to

deliver accurately metered quantities of fuel under

high pressure to the spray nozzle for injection into

the engine cylinders.

c.

An integral mechanical-centrifugal type

governor controls fuel delivery as a function of

engine speed. It is driven directly from the rear of

the pump camshaft without gearing.

d.

The fuel supply pump is the positive

displacement type. It is gear driven by the metering

and distributing fuel injection pump camshaft. It

provides fuel to the hydraulic head for injection and

cooling, and fuel to the engine flame heater system.

e.

The timing device is the mechanical-centrifugal

type. It is driven clockwise by the engine camshaft

at crankshaft speed.

f.

The fuel density compensator (when used) is

mounted on the governor housing. The fuel density

compensator automatically varies the quantity of

fuel delivered to the engine so that the maximum

power output of the engine remains constant

regardless of the type of fuel being used.

1-6. Injection Pump Housing.

a.

The aluminum

housing is cast with an integral three-hole flange for

mounting the advance unit. It has several drilled

holes that interconnect to form passages for the flow

of lubricating oil supplied to the fuel injection pump

from the engine.

b.

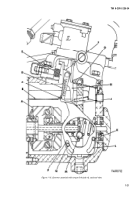

A quill shaft pad cover (F, fig. 1-13) on the

bottom of the housing provides for removal of the

quill shaft assembly during disassembly. A timing

window in the upper part of the housing covers the

marked plunger gear, which is used for timing

during assembly and disassembly. A timing pointer

(D, fig. 1-14) at front of fuel injection pump, alines

with a mark on timing device hub (C, fig. 1-14) to

show port closing position.

F

A

B

C

D

E

G

H

J

K

L

M

N

A

B

C

D

E

G

H

K

L

M

N

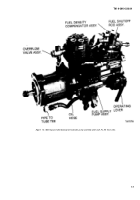

KEY to fig. 1-13

Typical Injection Pump

Code 13, C, D, E, F, G

Overflow valve assembly

Fuel control unit assembly

Fuel control rod

Fuel shutoff rod assembly

Timing window cover solenoid shutoff assembly.

Quill shaft pad cover

Camshaft driven gear

Shaft spacer

Quill shaft retaining screw

Quill shaft bushing

Quill shaft

Plunger sleeve pin

Plunger sleeve

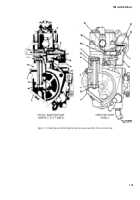

Injection Pump

Code A

Overflow valve assembly

Fuel control unit assembly

Fuel control rod

Fuel shutoff solenoid

Timing window cover solenoid shutoff assembly.

Quill shaft pad cover

Camshaft driven gear

Shaft spacer

Quill shaft retaining screw

Quill shaft bushing

Quill shaft assembly

Plunger sleeve pin

Plunger sleeve

F

J

1-14

Back to Top