TM-9-6015 - Page 21 of 54

easily on the pin (fig. 7) and the thumb nut locks firmly

into the bracket. The thumb nut should thread easily on the

sc rew tread which should be coated with lubricant and free of

corrosion. grit and dirt.

(4)

Forms and reports.

Authorized forms and reports for tech-

nical inspections are prescribed in TM 9-1100. For addi-

tional authorized forms and reports for field and depot main-

tenance, refer to paragraph 3.

(5)

Identification.

Inspect

lettering

engraved on case to see

that

it is clearly defined and easily read.

(6)

Paint and brush finish.

Inspect for bare spots or damaged finish

which expose base metal surfaces and lead to corrosion.

The

push fit between the reflector shade and case of the aiming

post light causes the paint on the case to be scraped off when

the reflector shade is removed.

This scraped off area and

other scrapes or scratches do not require a complete paint

refinishing of the light.

The area affected should be sanded

smooth with a fine grade No. 2 abrasive cloth and touched

up as required. Refer to TM 9-2851 for painting procedures.

(7)

Lubrication.

With the exception of the clamps on the

bracket, aiming post lights have no moving mechanical parts,

or parts subject to mechanical friction. Keep the thumbnut

or wing nut screw free of dirt and grit and lubricate the pins,

a

nd thumbnut and wing nut threads with a drop of light oil

applied once weekly.

(8)

Cracks.

Stamping and welds should be inspected for cracks

and breaks.

(9)

Spare parts and equipment.

Spare parts and equipment will

b

e checked against ORD 7 SNL F-205 for completeness.

(10)

Condition of optics.

Window and filter assemblies must be

free from scratches, pits, dirt, and chips as will interfere with

cleaning of their surfaces or which affect optical performance

of the aiming post light.

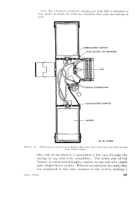

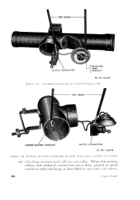

c. Inspection of Electrical Components

(figs. 4, 5, and 6).

(1) Aiming post lights are equipped with only one control which

is a single pole, single throw toggle switch. This switch

should move easily, with a sharp click, from the “OFF” to

“ON” position.

(2) Remove cover and cap assemblies and examine interior for

dirt, corrosion or acid action.

(3)

Examine

battery

cells

for

cracks

and

defects.

Cylindrical

insulating jackets must not be torn, discolored, or contain

foreign matter. Be sure not to use batteries on which the

service date limit, indicated on the jacket, has passed.

1 5

Back to Top