MWO-9-2300-378-34-2 - Page 17 of 92

MWO 9-2300-378-34-2

b.

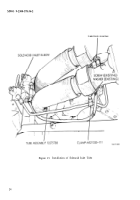

Installation of Solenoid Valve Assembly.

NOTE

The damper end (accessory end) or the engine will be

called the front and the transmission end the rear. As

viewed from the front of the engine toward the rear, the

side to the right will be called the right bank and the side

to the left will be called the left bank.

NOTE

During the following modification, clean all pipe

threads (both male and female) with dry cleaning

solvent PD-680 and apply teflon tape (antiseize

tape MIL-T-27730).

Lube threads of all tube fittings with technical

petrolatum VV-P-2 36.

(1) Remove protective plugs and felt filtering discs (if present) from inlet and outlet

ports of the solenoid valves.

NOTE

It may be necessary to reposition receptacle connector to

install nipple

AN911-2.

If connector

must be

repositioned, secure valve in a soft-jawed vise (or wrap a

rag around valve and secure in vise) and loosen acorn nut

on top of valve and reposition connector.

(2) Apply teflon tape to threads of pipe nipple AN911-2 and install nipple between

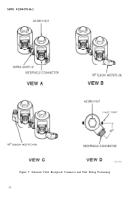

outlet port of one solenoid valve and inlet port of the other (figure 5, view A). The bottom

surfaces of the valves must be parallel.

(3) Place solenoid valve in soft-jawed vise or in vise with rag. Apply teflon tape to

threads of 90 elbow, MS518 15-36 and install in solenoid valve inlet port. Tighten to five

o’clock position (figure 5, view B).

(4) Place the second solenoid valve in soft-jawed vise or in vise with rag. Apply

teflon tape to threads of 90

elbow MS51815-36 and install in solenoid valve outlet port.

Tighten to twelve o’clock position (figure 5, view C).

(5) Check position of receptacle connector on each solenoid valve 11668627-2.

Connector should be positioned 45° from inlet port as shown in figure 5, view D. If connector

must be repositioned, secure valve in a soft-jawed vise (or wrap a rag around valve and secure

in vise) and loosen acorn nut on top of valve.

Reposition connector and torque nut to

50 lb.-in. (5.6 n.m).

15

Back to Top