TB-9-2320-335-13-P - Page 210 of 680

TB 9-2320-335-13&P

7-30

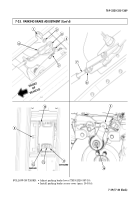

7-12.1. SERVICE BRAKE ROTOR REPLACEMENT

(SERIAL NUMBERS 300000 AND ABOVE)

This task covers:

a. Removal

b. Installation

INITIAL SETUP:

Tools

General mechanic’s tool kit:

automotive (Appendix B, Item 1)

Maintenance and repair shop equipment:

automotive (Appendix B, Item 2)

Materials/Parts

Sealing compound (Appendix C, Item 62)

Six two-piece lockwashers

(Appendix A, Item 191)

Manual References

TB 9-2320-335-13&P, Appendix E

Equipment Condition

•Service brake caliper removed (para. 7-4.1).

•Parking brake pad removed (rear only)

(para. 7-22).

Maintenance Level

Unit

NOTE

Replacement procedures for all rotors are basically the same.

This procedure covers the front rotor.

1.

Remove six capscrews (5) and two-piece lockwashers (4) from halfshaft (3), rotor (2), and output

flange (1). Discard two-piece lockwashers (4).

NOTE

Clean excess sealant from output flange threaded holes with a

10 mm tap.

2.

Disconnect halfshaft (3) and remove rotor (2) from output flange (1).

NOTE

• Use capscrew to align rotor to mounting holes until halfshaft is

installed.

• New capscrews come with pre-applied thread-locking compound,

however, still apply sealing compound to threads of new

capscrews. If old capscrews are to be used, mating threads must

be cleaned and sealing compound applied to threads of capscrews.

• Two-piece lockwashers must be installed in sets of two with

serrated sawtooth threads facing each other.

1.

Install rotor (2) on output flange (1).

2.

Install halfshaft (3) on rotor (2) with six two-piece lockwashers (4) and capscrews (5).

Tighten capscrews (5) to 58 lb-ft (79 N

•

m).

b. Installation

a. Removal

Back to Top