TB-9-2320-335-13-P - Page 222 of 680

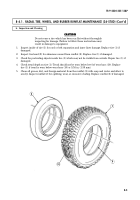

8-4.1. RADIAL TIRE, WHEEL, AND RUBBER RUNFLAT MAINTENANCE (24-STUD)

This task covers:

a. Disassembly

c.

Repair

b. Inspection and cleaning

d.

Assembly

WARNING

• Do not use tire machine. Injury to personnel or damage to

equipment may result.

• In all disassembly operations, ensure the tire is totally deflated

before removing wheel locknuts. Failure to follow proper safety

precautions could cause serious injury or death to personnel.

1.

Remove valve core (7) from insert (8) and deflate tire (6).

2.

Use a circular pattern and loosen twenty-four wheel locknuts (2) securing rim halves (1) and (5)

together. If you hear escaping air, do not proceed. Wait until sound stops. When tire (6) is fully

deflated, remove wheel locknuts (2). Discard locknuts (2).

a. Disassembly

TB 9-2320-335-13&P

8-2

INITIAL SETUP:

Tools

General mechanic’s tool kit:

automotive (Appendix B, Item 1)

Maintenance and repair shop equipment:

automotive (Appendix B, Item 2)

Special Tools

Runflat compressor (Appendix B, Item 115)

Torque adapter, 9/16-in. (Appendix B,

Item 133)

Socket adapter (Appendix B, Item 135)

Materials/Parts

Twenty-four locknuts (Appendix A, Item 84)

O-ring seal (Appendix A, Item 280.3)

Locknut (Appendix A, Item 86)

O-ring (Appendix A, Item 232)

Lubricant (Appendix A, Item 192)

Detergent (Appendix C, Item 25)

Sealing compound, if required

(Appendix C, Item 61)

Manual References

TM 9-2320-387-10

TM 9-2320-387-24-1

TM 9-2610-200-14

TB 9-2320-335-13&P, Appendix E

Equipment Condition

Wheel removed (TM 9-2320-387-24-1).

General Safety Instructions

• Do not use tire machine.

• Ensure tire is totally deflated before

removing wheel locknuts.

• Never use tubes in wheel assemblies.

• Rim surfaces must be kept clean and free of

rust and dirt.

• Never use wheel assemblies with damaged

studs.

• Never inflate a wheel assembly with the

wheel locknuts removed.

• Never inflate a wheel assembly without

first checking wheel locknut torques.

• Do not exceed recommended tire inflation

pressure.

• Always use an OSHA approved tire

inflation cage and a clip-on air chuck for

tire inflation.

• Ensure runflat compressor strap is centered

around runflat.

• Never install radial tire on eight-bolt wheel.

Maintenance Level

Unit

Back to Top