TB-9-2920-225-34-1 - Page 61 of 70

TB 9-2920-225-34-1

d. Transistors.

NOTE

Transistors Q4 and Q5 can be checked

fairly accurately without removing them

from the circuit.

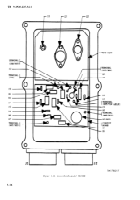

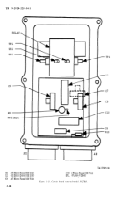

(1) Check transistors Q4 and Q5, (see fig.

4-3), inaccordance with figures 4-l and 4-2.

NOTE

Due to the connection

cuit, omit the emitter

in figure 4-2.

(2) If other readings

transistors Q4 and Q5.

of Q4 in the cir-

to collector check

are obtained, replace

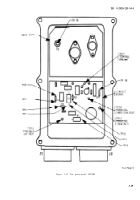

e. Circuit Board.

If no faulty components were

detected after performing tests a, b, and c, replace

the circuit board.

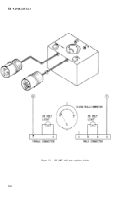

f. Functional Check.

Check the performance of

the regulator on the test stand and make final

voltage adjustments. Voltage output should read

28 volts. If the regulator does not function prop-

erly, perform the following:

(1) Check wires and connections.

(2) Replace circuit board.

(3) Perform bench test procedures.

NOTE

After final repair, check regulator on the

test stand.

If the regulator still does not function correctly it

will be necessary, if local skills permit, to test

each component. All the parts should be checked

with an ohmmeter and the capacitors checked with

a capacitance meter. The circuit board traces

should be checked with an ohmmeter to ensure

that there are no cracked traces. Traces with hair-

line cracks will show good at lower temperatures

and will tend to show open circuit at higher tem-

peratures. If the board seems good at room tem-

perature, but the regulator still fails, this could

be the cause.

Table 4-1. Replacement Parts List-

Leland Airborne Model

4-4

Back to Top