TB-9-2920-225-34-1 - Page 52 of 70

TB 9-2920-225-34-1

Section V. LEECE-NEVILLE MODEL R0015027RD

3-10. General.

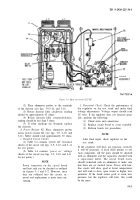

Figure 3–12 is a plan view of the

regulator with the cover removed, showing the

heat sink and the circuit board. The components

are indicated by their reference designations, and

on the circuit board the terminals are associated

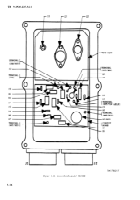

wire colors are also indicated. Figure 3–13 is a

plan view of the regulator with the cover, heat

sink and circuit board removed, showing the relay

and remaining components. The components are

indicated by their reference designations, and test

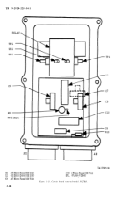

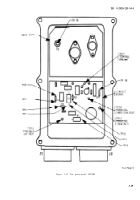

points 1 through 5 are shown. Figure 3-14 is a

plan view of the regulator with the cover removed,

showing test points 6 through 18. There are 18

total test points. Figure 3-15 is an electrical sche-

matic diagram of the regulator circuit.

3-11. Checkout and Repair.

a. Relay (see Figs. 3–13 and 3–14) (power dis-

connected).

(1) Place positive probe of ohmmeter on pin

F of connector J2 and negative probe on TP1

(white/yellow wire). Meter should read low ohms

(hundreds).

(2) Reverse probes. Meter should read high

ohms (thousands).

(3) If other readings are obtained, see de-

tailed circuit check below.

(4) Place ohmmeter positive probe on TP2

and negative probe on TP1. Meter should read

approximately 50 ohms.

(5) Reverse probes. Meter should read low

ohms (more than 10 and less than 100).

(6) If other readings are obtained, discon-

nect the WHT/YLW wire on TP1 and repeat (4)

and (5) looking for a meter reading of 40 to 60

ohms in each case. If other readings are obtained

replace the relay, NSN 5945–00-409-3883. Re-

place the WHT/YLW wire on TP1.

(7) Place ohmmeter probes on TP3 and TP4.

Meter should read infinity (open circuit). If other

readings are obtained replace the relay, NSN

(8) Place positive ohmmeter probe on TP17

and negative probe on TP8. The reading should

be greater than 10 ohms and less than 100 ohms;

if not replace Ql, NSN 5961–00–730–3284.

(9) Place positive ohmmeter probe on TP12

and negative probe on TP13. Rotate the potenti-

ometer. Full counterclockwise should be 0 ohms,

gradually increasing to 100 ohms at full clockwide.

If not, replace the potentiometer. The potenti-

ometer is a 100 ohm, 2 watt, tab-mounted device.

Failed devices have been successfully replaced

with part number 71590–WT-100 by performing

some minor mechanical modification.

Globe-Union Inc. FSCM 71590

Centralab Electronics Div.

Hwy. 20 W. P.O. Box 858

Fort Dodge, IA 50501

(10) Place positive ohmmeter probe on TP15

and negative probe on TP16. The reading should

be greater than 10 ohms and less than 100 ohms;

if not, replace D3.

b. Resistor R10.

(1) Place ohmmeter probes on pins D and E

of connector J2. Meter should read approximately

0.4 ohms.

(2) If other readings are obtained, replace

resistor.

c. Resistor R9.

(1) Place ohmmeter probes on TP5 and pin

C of connector J2. Meter should read 0 ohms plus

(resistor is actually rated at 0.05 ohms).

(2) If other readings are obtained, check the

wiring from the bottom terminal of the resistor

to pin C on connector J2. If the wire continuity is

good, replace the resistor.

d. Detailed Circuit Checks.

Table 3–5 contains

“power off” resistance checks of the circuit (see

figs. 3–12, 3-14 and 3-15 for test points).

e. Functional Check.

Check the performance of

the regulator on the test stand and make final volt-

age adjustments. Voltage output should read 28

volts. If

perform

(1)

(2)

(3)

the regulator does not function properly,

the following:

Check wires and connections.

Replace cover assembly.

Perform bench test procedures.

NOTE

After final repair, check regulator on the

test stand.

If the regulator still noes not function correctly

it will be necessary, if local skills permit, to test

each component. All the parts should be checked

with an ohmmeter and the capacitors checked with

a capacitance meter. The circuit board traces

should be checked with an ohmmeter to ensure

that there are no cracked traces. Traces with

hairline cracks will show as good at lower tem-

peratures and will tend to show open circuit at

higher temperatures. If the board seems good at

room temperature, but the regulator still fails,

this could be the cause.

3-15

Back to Top